You’ve probably heard the old saying, “It takes a village to raise a child.” Well, it takes a factory to make a GS Mini. By the time a completed guitar is placed in its protective case after final inspection, countless craftspeople have literally had a hand in bringing the guitar to life.

Since its debut in 2010, the GS Mini has been made at our manufacturing complex in Tecate, Baja California, Mexico. Located 43 miles from our U.S. headquarters in El Cajon, California, our Tecate operation currently fills a 119,000-square-foot building that we expanded into in 2014 after occupying several smaller buildings in an older business park. The current business park is one of the nicest in the region and is built on land that was formerly a vineyard. We designed and oversaw the construction of the facility to optimize the flow of our production processes, which include making hardshell cases and many of our gig bags. The facility also includes an employee cafeteria.

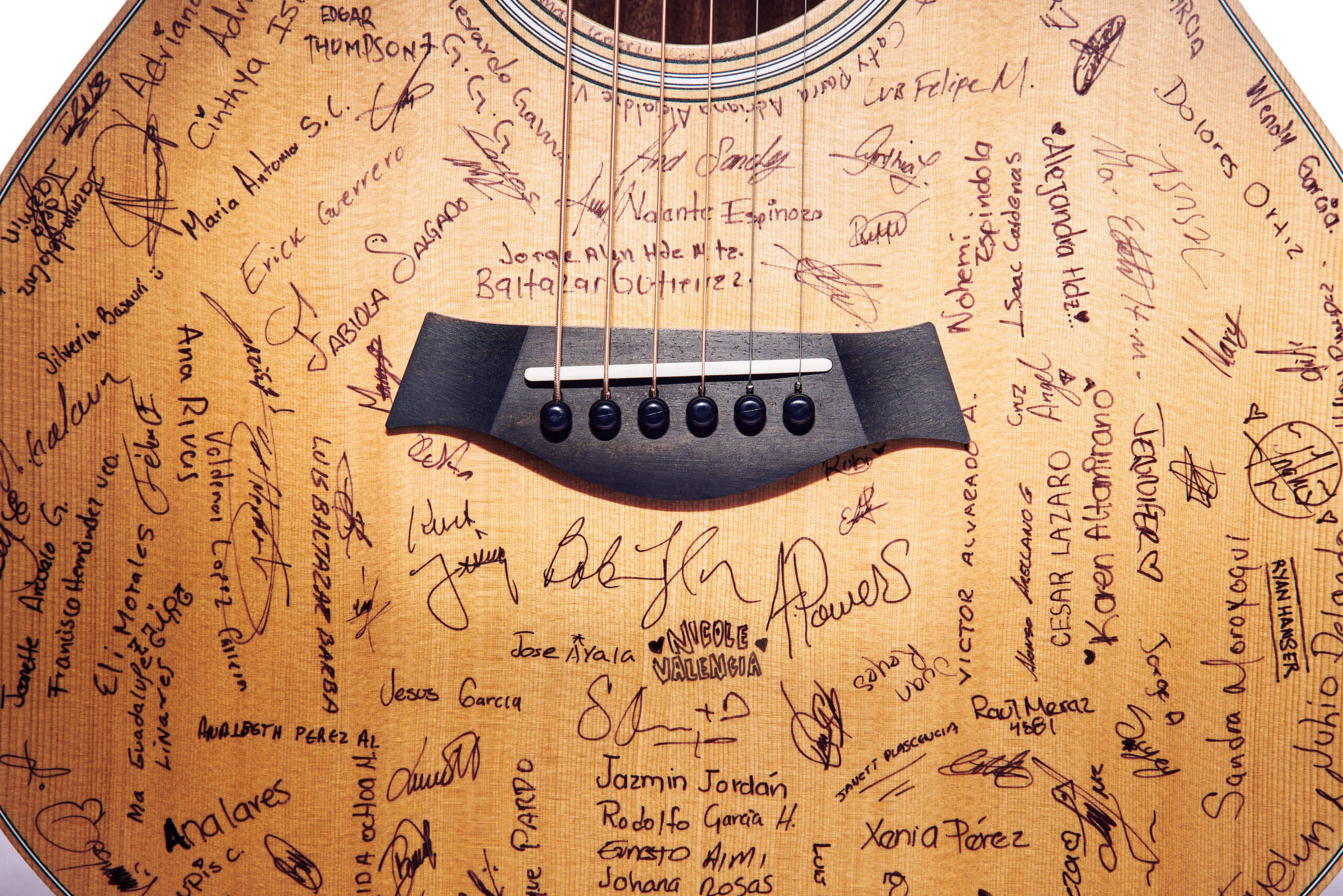

To commemorate this year’s milestone of 500,000 GS Minis made, we invited our Tecate employees to sign one of the guitars. According to Manufacturing Manager Randy Johnoff, of the more than 400 employees there, we were able to get about 300 signatures. Talk about getting inked up! The signatures cover the entire guitar, including the neck and back of the headstock.

To tie in with Taylor’s other milestone of our 50th anniversary, co-founders Bob Taylor (a proud design parent of the GS Mini) and Kurt Listug, along with chief designer, President and CEO Andy Powers (who designed the GS Mini Bass), also signed the guitar. We’ll be keeping it here in the Taylor guitar archives for posterity.