What could a veterinarian, a bartender and a dancer know about supplying wood to musical instrument makers?

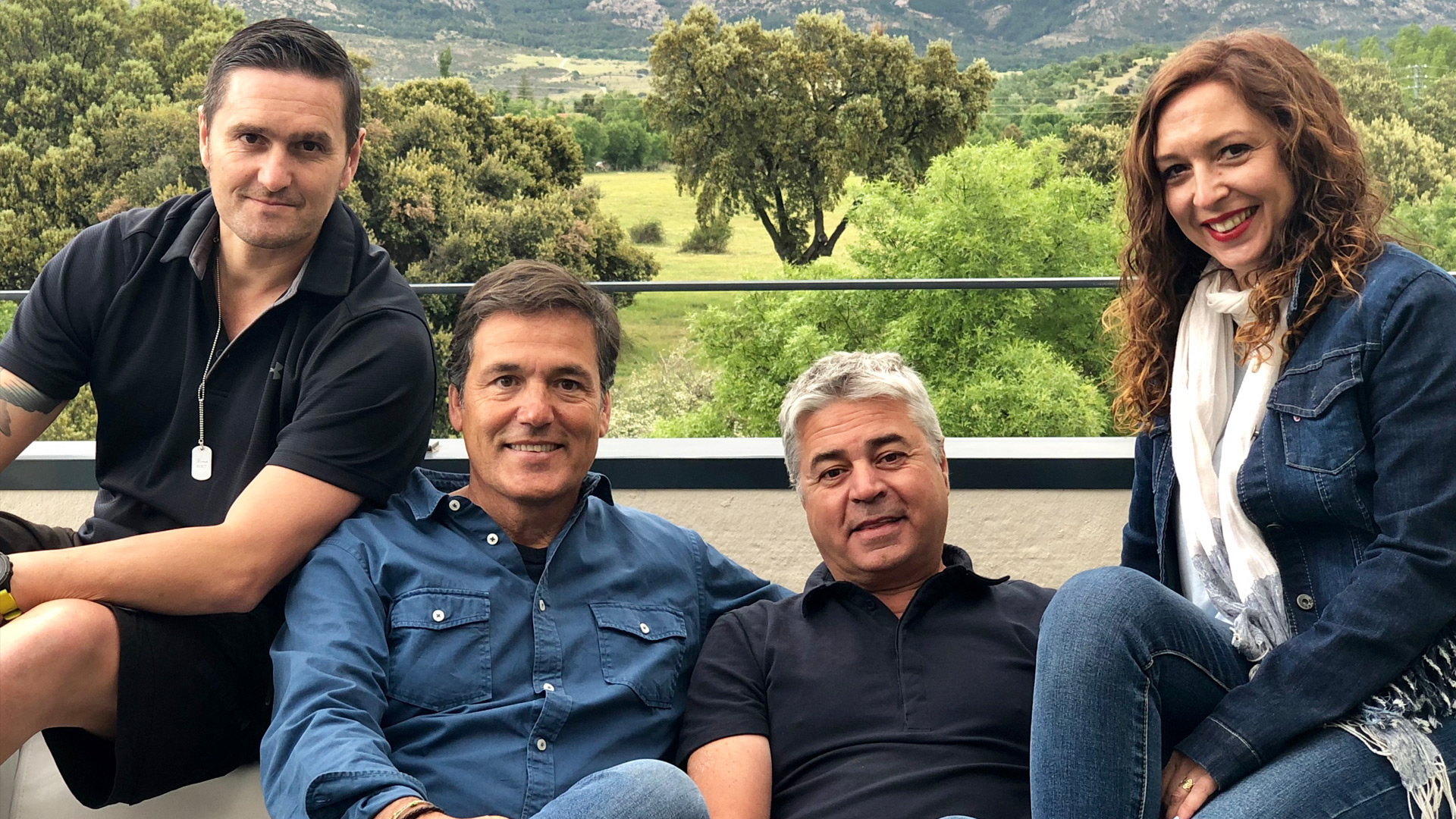

Actually, quite a lot, but 20 years ago, when their company, Madinter, was launched, there was still much to learn as each pivoted to a new career path together. Co-founder, CEO and majority owner Vidal de Teresa (the veterinarian), Production Manager Jorge Simons (the bartender) and Sales Manager Luisa Willsher (the dancer), along with co-founder and silent partner Miguel Ángel Sánchez, form the core management team for the company, which supplies tonewoods and finished parts to makers of musical instruments, including Taylor.

Madinter and its 20 employees are based in the Spanish town of Cerceda, located in the province of Madrid, Spain — about 45 minutes from the city center. You might recognize the name Madinter (a contraction of Madera, the Spanish word for wood, and International) from our reports on ebony in Cameroon, as Madinter is our ownership partner in the Crelicam ebony mill. That partnership, now in its tenth year, is a testament to the shared commitment both companies have made to ethical sourcing practices, and to creating more sustainable forest economies that support the livelihoods of the local communities involved in the sourcing supply chain.

Though a relatively small company, Madinter has grown in many ways over the past two decades, leading the way in raising the standards of sustainability, legality and responsibility among timber suppliers. To help celebrate the company’s 20th anniversary, we wanted to connect the Taylor community with our valued partner and spotlight the important role they play in supporting a vibrant global music community and responsible forest stewardship.

We chatted with Luisa and Vidal via email. They shared the personal journey that brought each of them to Madinter and reflected on the company’s ongoing evolution in pursuit of its vision.

Tell us a bit about the town of Cerceda, where you’re located.

Cerceda is a small village of about 2,500 people located in the mountains of Madrid, about 30 minutes from Madrid Barajas International Airport. We are next to Sierra de Guadarrama National Park, in the north of the province of Madrid, a unique location for its natural environment. The Sierra de Guadarrama is full of stunning places due to its beauty and its geological and biological richness. Here you will find immense coniferous forests, high mountain meadows, snowy landscapes, enormous rocky peaks, streams, waterfalls and glacial lakes, making up an environment of special natural value that is home to endemic species and some in danger of extinction in Spain.

What might people find interesting about the design of your facility? For example, one of your buildings has an interesting façade — it looks like an artistic interpretation of tree trunks.

Yes, it’s a unique façade made of corten steel with a patina, which imitates the silhouette of a coniferous forest, very similar to those we have in our surroundings. The pieces simulate tree trunks of wild pine, the most representative tree in the national park. We wanted to make a small tribute to our forests and to wood.

Our buildings have solar panels on their roofs to make our business more sustainable and minimize our carbon footprint. We also burn our sawdust in furnaces and use the heat for our kilns where we dry our wood and also to warm the buildings in the winter.

How was the company established?

Prior to the founding of Madinter, Miguel had a company that sold wood to guitar craftsmen and that also sold guitars, helping craftsmen export their guitars to other markets. In 2001, Miguel and Vidal founded Madinter, and Jorge and I joined the team shortly afterwards. Now Madinter specializes solely in producing and selling parts for musical instruments.

In 2003, Miguel left Madinter to become a silent partner and created another company dedicated to the manufacture of flamenco shoes, Calzado Senovilla. Due to his experience with guitar woods, he decided to use these same woods and incorporate them into the manufacture of the shoes. Today, these shoes have a great reputation and are worn by the best flamenco dancers all over the world.

Vidal, you were a veterinarian, so starting Madinter was quite a career change. What was your motivation?

In 2001, after 11 years as a veterinary surgeon, I sold my company and found myself at a personal crossroads. I loved my profession, which had always been my vocation, but I had other passions outside veterinary medicine. These included traveling, getting to know the rainforests, and starting a new business venture. The world of luthiery was not alien to me because when I was studying veterinary medicine in Paris, Miguel would send me wood, and when I had time between my studies and practice at the veterinary school, I would visit luthiers and offer them these woods. This brought me extra money and allowed me to discover the exciting world of wood, guitar makers and music.

The great master luthier Daniel Friederich was my first customer. I went into his workshop in the Faubourg Saint-Antoine district, near the Bastille in Paris. He was carrying a handful of sets of rosewood sides and backs. I was an inexperienced young man, but very curious. He took exquisite care of me and showed me the nooks and crannies of his workshop and instructed me on the wood I was carrying. It was a fairy-tale workshop, full of wood aromas and shavings, of guitars in the process of construction. That day I became interested in learning more about that trade, about those woods, where they came from, how they were cut, how they were dried. That was the seed that ignited a passion in me and made me change my career years later and start an exciting new story.

Luisa, you’re originally from the UK and studied dance. How did you get involved with Madinter?

I was born and raised in England, and at 10 years old I went to a performing arts boarding school until I was 18. We were trained mainly as ballet dancers but also studied other dance genres, and I immediately fell in love with flamenco. After visiting Spain a few times for short dance courses, at 18, I was offered my first job and moved to Spain knowing that I would never return to England for good. At 24 years old, while rehearsing, I broke my foot. By this time, Madinter was taking its first baby steps with Vidal, Miguel and Jorge, and to keep myself occupied, I helped them out, translating and writing to clients. Back then all correspondence was by letter or by fax. We bought our domain, www.madinter.com, started writing emails, set up our first web page, and began our continuous improvement. By the time my foot was healed and I could have gone back to dancing, I was so involved and enjoying the work I was developing at Madinter I never left. Now the only dancing I do is for fun.

Your range of products and services has expanded a lot over the years after starting exclusively as a wood supplier. How has your business evolved?

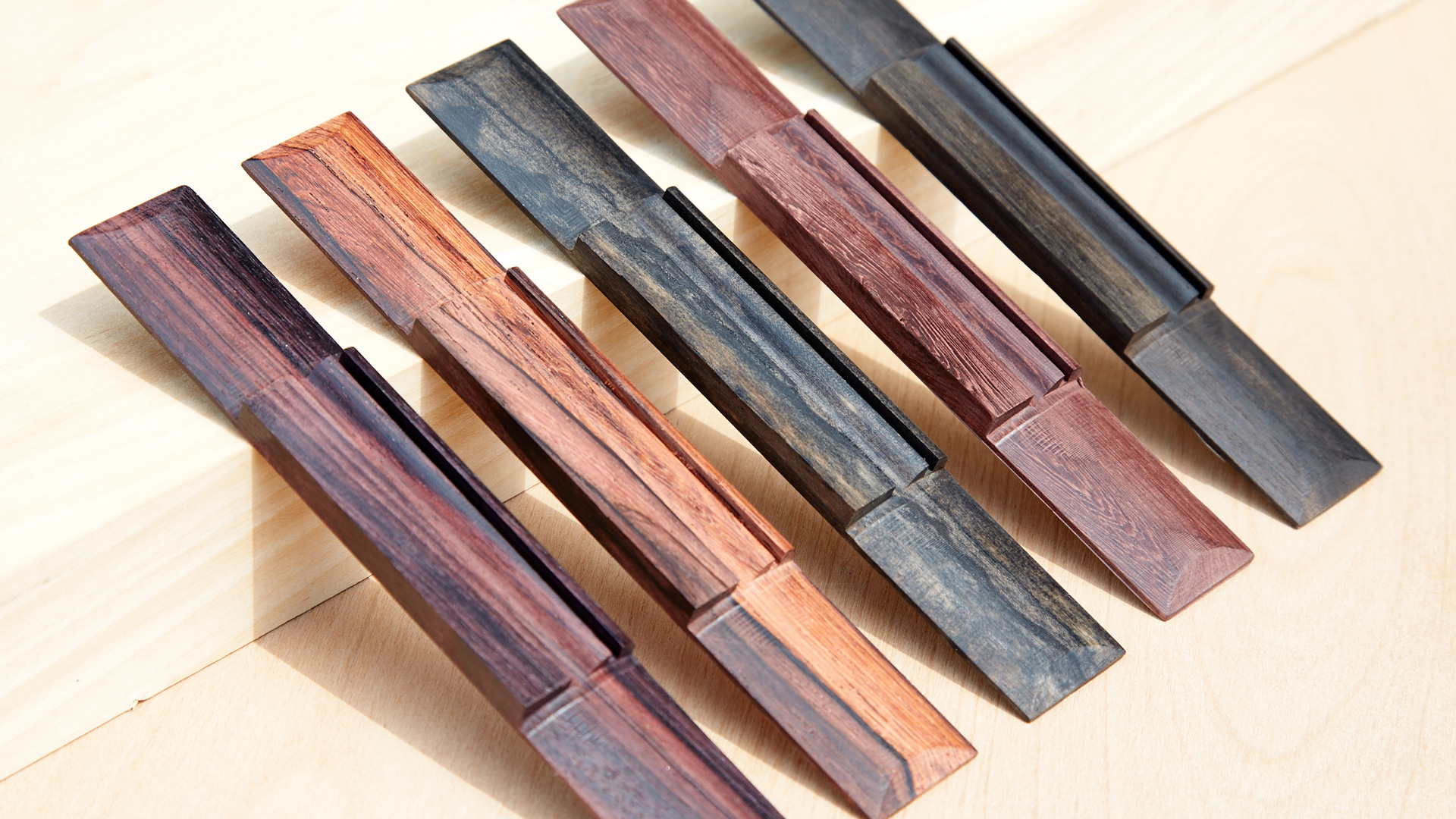

In the beginning, we only supplied wood to musical instrument manufacturers. We started with half a dozen species of wood. Today we offer more than 40 different species for making musical instruments, especially guitars, and we also supply components, accessories and tools. We have also become more specialized in manufacturing finished musical instrument parts using unique and precise machinery, enabling us to add more value to the raw material. As a result, our business model has changed a lot in recent years. We no longer only supply musical instrument manufacturers, but also the craftsman and the hobbyist instrument maker. Our website has become a resource hub in the industry because we offer a large range of products and solutions. We cut the wood, dry it, process it, make finished parts ready to assemble instruments, and we also manufacture customized products for several clients. We work with factories, workshops and makers all over the world. And for three years now, we have been distributing StewMac products in Europe, and we are their sole distributor apart from themselves.

“Over the last 10 years, we have seen many new young guitar makers or even amateurs who are attracted by the do-it-yourself culture and are starting to build instruments.”

Spain has such a rich guitar-making heritage, and as I understand it, there currently are many luthiers there. Can you provide some perspective on that and how it impacts your business?

Spain is a country with a great tradition in classical and flamenco guitar making. We have a lot of guitar makers and very good ones. Over the last 10 years or so, we have seen many new young guitar makers or even amateurs who are attracted by the do-it-yourself culture and are starting to build instruments. Many of them are attracted because they are musicians and would like to know how to make the instrument they play, and others because they have a knowledge of cabinetmaking and would like to learn how to make guitars and diversify their activity. In any case, the determining factor in this explosion of new luthiers is Madinter and similar companies that have supplied a wide variety of products to the market, making it possible to find everything needed to build a musical instrument, from materials and finished products to all kinds of components, accessories and luthier tools. There are also many luthiers all over Europe, and through Madinter.com we can reach all of them. Our customer base has diversified enormously and continues to grow month by month.

Luisa, in a previous email you said that one of Madinter’s keys to success has been the ability to adapt to change. Can you elaborate on this in any specific ways? One thought that comes to mind is the way legal compliance requirements have changed over the past two decades with regulations like the amendment to the Lacey Act or changes in the status of certain wood species with CITES or EU timber legislation.

We have adapted to change in many ways over the last 20 years, but one key factor was indeed our decision to focus on legality. When the Lacey Act was amended to include musical instruments, Madinter was already emphasizing the importance of our wood being legally and responsibly sourced. So when the industry realized that they too needed to make sure that they were purchasing legal wood, Madinter had a solid due diligence system in place and vast knowledge of compliance, CITES, etc.

Some other examples: In our early years we set up our first online store at Madinter.com, which no others had. We visited Asia and started offering solid wood to Chinese factories before any of them even made solid-wood guitars! We also broadened our catalogue to meet our clients’ needs and diversify our business. We added components, accessories and tools, and we are very proud that StewMac trusts Madinter to be their sole distributor other than themselves.

Also, new luthiers were no longer the sons of the older generations. They were newcomers learning the trade, so we started to offer guitar-making courses.

In addition to your range of products and services, what do you think sets you apart from other companies?

Our vision as a company is to lead the music industry in championing a sustainable forest economy by maintaining the highest standards of sustainability, legality and responsibility in our timber sourcing. Right from the start, we decided that we did not want to be another company just cutting down trees. We wanted to do things correctly. To start with, we wanted to make sure every single piece of wood was sourced legally, complying with all national and international laws. This should be obvious and standard, but unfortunately it is not. And then go a step further and make sure that the environment, the people, are not being harmed, and if we can, to have a positive impact on the world.

It’s not only Madinter’s 20th anniversary this year, but also the tenth year of Madinter and Taylor’s Crelicam partnership. How would you reflect on what our two companies have managed to accomplish so far and what it means for Crelicam employees and other sawyers and supply partners in Cameroon?

We are very proud of this partnership and how much we have achieved together. In just 10 years, we have changed many things and always for the better. When we acquired Crelicam and designed the logo, we also added a slogan that we have stuck to: Responsible Trade. Looking back at what we have achieved together, we are very pleased. Together we have managed to get the industry to accept the ebony that it did not use before because it was too light in color; we have improved the living conditions of our workers, collaborators and the people who live around the factory; and we have improved the health, technological conditions and professional qualifications of our employees. And as the cherry on top, we have launched the Ebony Project in order to plant and perpetuate the use of ebony for future generations.

During these years, we have also received recognition from the music industry and from the governments of the U.S., Spain and the EU, which have awarded and publicly acknowledged our work in Africa. But the most important thing is that this is not over. We still have many ideas, projects and improvements that we want to implement in the years to come.

What do you value about your relationship with Taylor?

Often, we recall the first time we proposed the Crelicam acquisition to Bob [Taylor] and how he welcomed the idea and his enthusiasm from the very beginning.

In 2010 we went to Amsterdam because we knew that Bob, Kurt and CFO Barbara Wight were meeting in the Netherlands with their European distribution team. We called Bob a few days in advance and told him we wanted to present him with a business proposal. We had spent weeks working on an elaborate business plan and had a long presentation to make with a lot of ideas and numbers. When we arrived at the hotel where Bob was staying and introduced the idea to him, he immediately cut the presentation short and said, “I like the idea, and we are going to do it together.” Half an hour later, together with Bob, Kurt and Barbara, we were planning our first trip to Cameroon. And so began this wonderful adventure.

Working with Taylor Guitars has been the best thing that has happened to us over the last few years. We have found a group of fantastic professionals and wonderful people. A special mention must go to our great friend and mentor, Bob Taylor — a wonderful person with a big heart, with unique intelligence and brilliance, a tireless worker as well as a visionary in the music industry. We have learned together and made mistakes together, but we have always moved forward and will continue to move forward toward excellence.