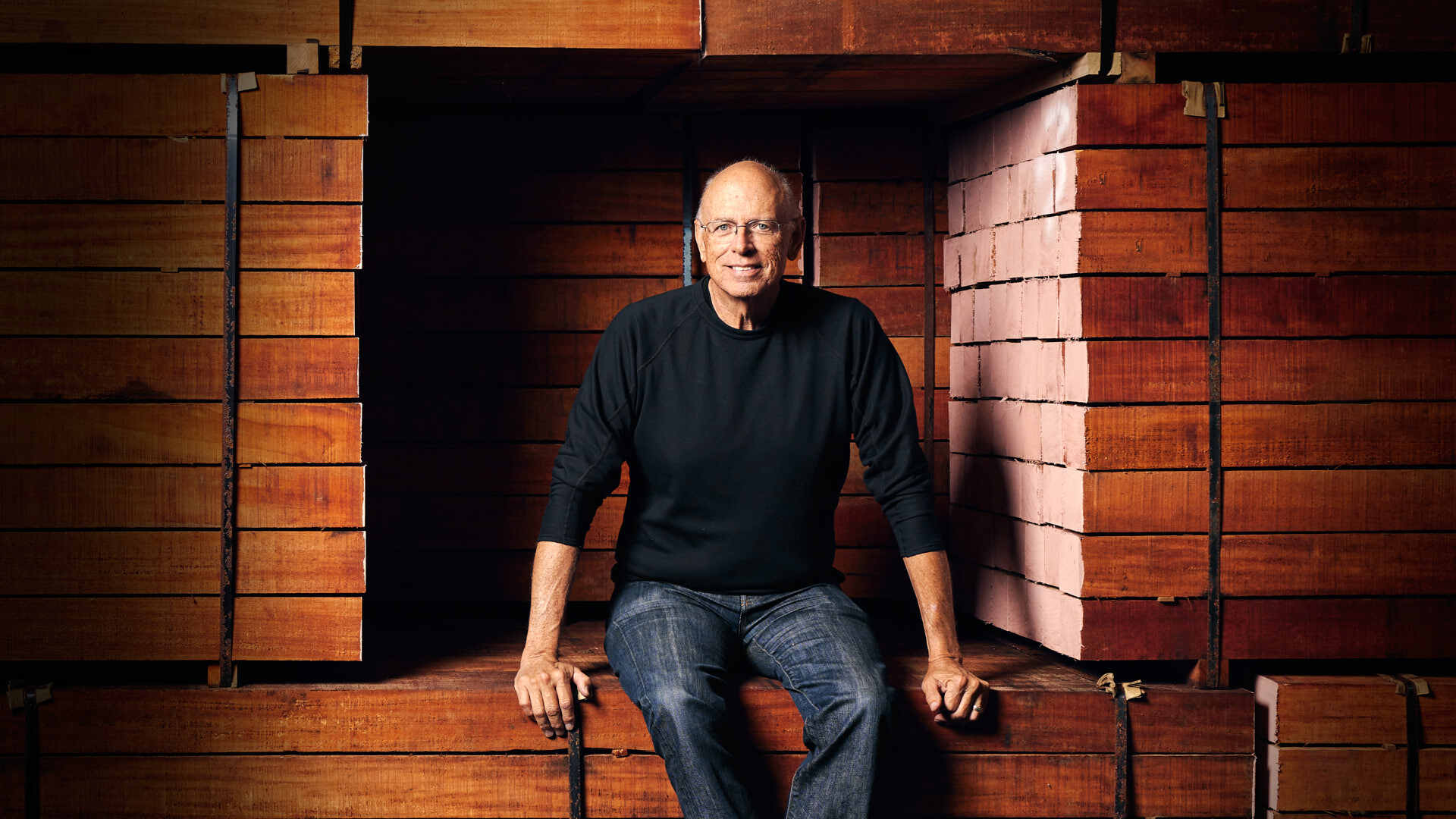

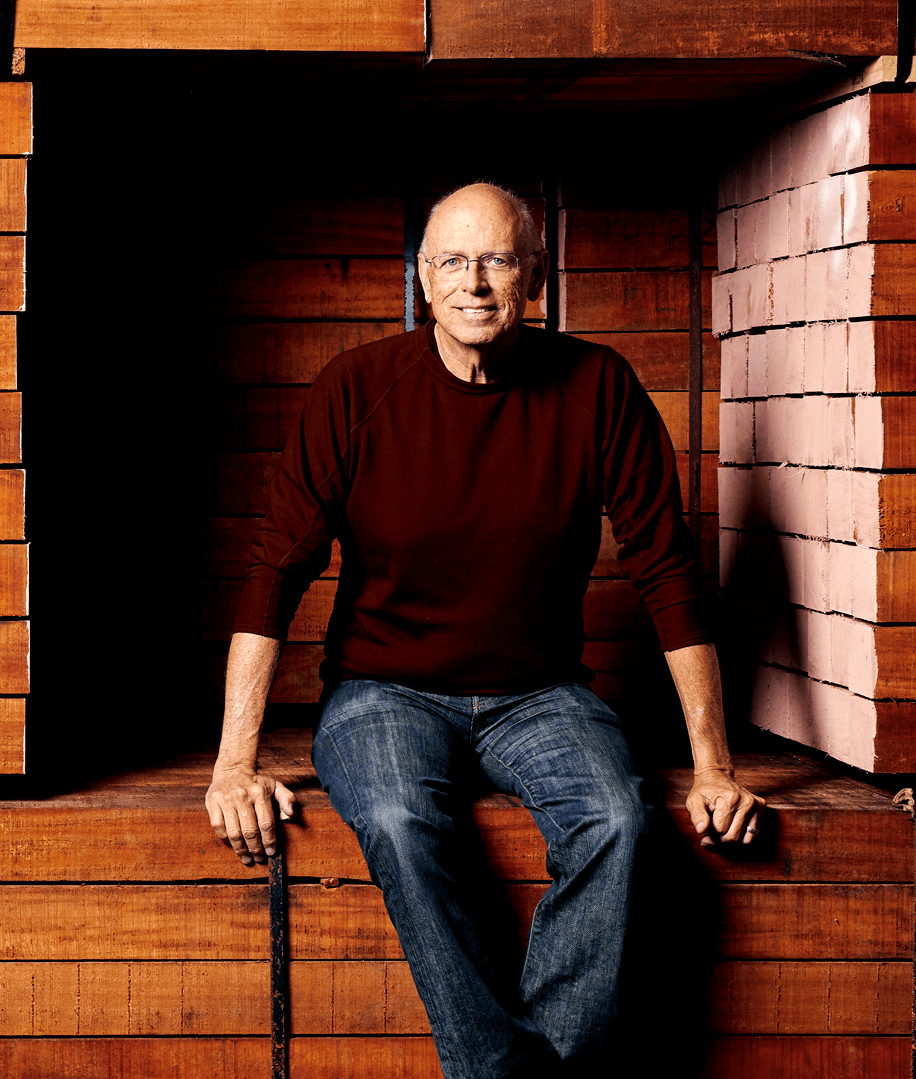

Taylor Guitars was born on October 15, 1974, so I have three-quarters of this year left to go before I can say this is officially our 50th anniversary. But on that day I intend to lift a glass. Still, we’re into our 50th year, and I can’t help but reflect. I was told recently that when Fender reached their 50th anniversary, Leo Fender had been gone 29 years. Well, folks, I’m still here, hard to get rid of, and happy to say it’s been the joy of my life to have such a rich passion and career, and that I am jealous of no one.

When I think of the chapters that make up the last 50 years, they were all meaningful little epochs. The first years of finding satisfaction from working day and night with my hands, developing my skills as a guitar maker, and learning how difficult it was to get it all right. Living through the days of being unknown and not being able to sell enough guitars to make things work. Setting up our first trade show booths, being full of excitement to show our guitars, that wonderful smell of freshly printed color catalogs that cost us our last red cent, and the smell of new carpet in the aisleways. Building the smallest of a factory and adding to it in tools and craftspeople. Training people to make a guitar body, a neck, putting a good finish on the guitar. Frets, tapped into fingerboards with a hammer, dressed with a sanding block and files.

Things got easier as the factory and the team grew in ability. Then came the reality that the wood we used was in shorter supply and regulated more each year. Words like “sustainability” started to have meaning, not only for the long future but for the near term. While this was becoming apparent in my mind, our guitars started growing up as we developed our own unique shapes, styles and trade dress. We grew proud that although we were coming late to the party, in style, sound and feel, we were unique. We were Taylor Guitars; we weren’t copies of the other brands. This isn’t the easiest thing to accomplish, but it happened, slowly but surely.

Our production grew. We became an important part of the market. We acquired haters! You know you’re making some kind of impact when people criticize virtually everything you make, say, sell and think. On the other hand, we had lovers. People who loved our guitars, and in fact, the hard numbers showed that a little more than 40 percent of guitar buyers voted with their wallets in our favor. Still, the haters affected me inside, even when we had success.

The day came to put more effort into where and how our wood makes its way to our doors. In some cases, there’s no problem, like with our friends at Pacific Rim Tonewoods in Washington State, or Gemwood in India, or Madinter in Spain. But in other cases, it felt best to be more involved to the point of making partnerships where we could, and that came with both ebony wood and koa wood. Thus, we went into partnerships with Madinter on ebony in Cameroon, and Pacific Rim Tonewoods with koa in Hawaii. What good decisions those were. Then came West Coast Arborists, who allowed us to source end-of-life urban trees of California, with which we’ve made thousands of guitars.

We grew proud that, in style, sound and feel, our guitars were unique; they weren’t copies of the other brands.

Along came Andy Powers, who joined our team as Chief Guitar Designer. He has haters too. I feel better now. But again, he’s got lovers. And we made a good partnership with him, literally through equity in the company — the first time Kurt and I took on another partner in Taylor ownership.

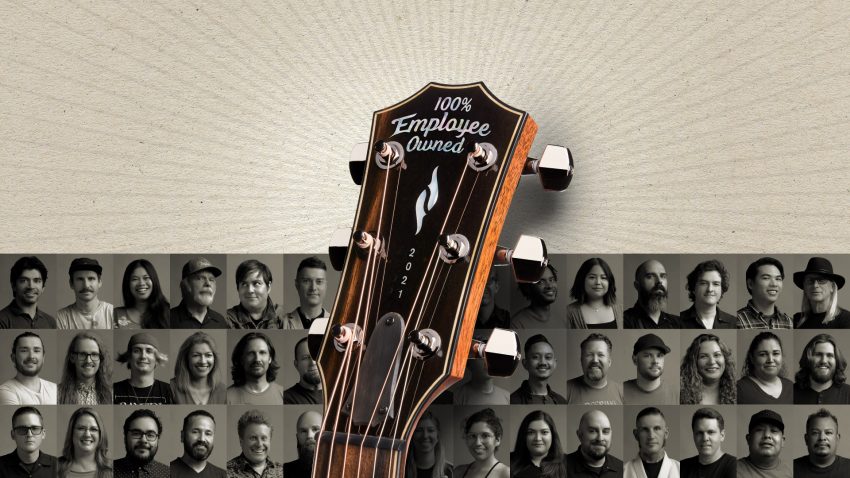

There was the day we became 100-percent employee-owned, intended to keep Taylor as close to what it was, and is, long into the future as Kurt and I age out. Father Time always wins in the end, so why deny that, and this is how we faced that eventuality. Afterward, we made Andy President and CEO. Yes, there are changes, but we make them as best we can.

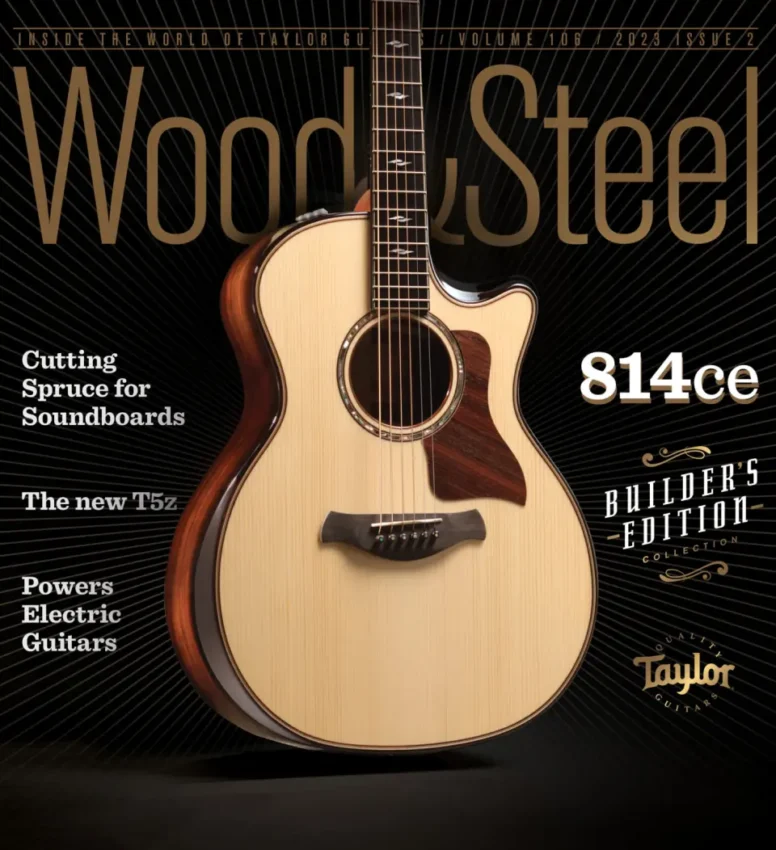

Fifty years of changes. Factories in the U.S. and Mexico, our own distribution nearly worldwide, wood operations in Cameroon and Hawaii. Tax returns in more countries and states than I can remember to cite. Laws, regulations, employees, cultures, languages. For those of you reading this, you may not realize we print our Wood&Steel product guide in six languages.

These are the epochs of Taylor Guitars over 50 years, at least as I think back on our experiences. It’s really something to me. It’s humbling to know that you are reading this because you like our guitars and are interested in our company. Of course, the backbone of all this is the guitar and you the player. That’s what it’s all about.

So, in 800 words, you’ve read our 50-year history. But if you want more, Kurt and I have recorded podcasts recounting our history together that we will release this year in episodes. We talk in depth. We remember. There are some great stories there that even I like hearing! If you’re curious, I hope you have a listen.

Thank you for 50 years!