Ed. Note: Taylor’s master builder, Andy Powers, answers this round of questions, with Bob Taylor sharing the origin story of Taylor’s iconic headstock design.

How much does the type of wood chosen for a guitar fretboard affect the sound of an acoustic? Read Answer

The fretboard of an acoustic guitar matters because everything matters. The neck of a guitar (including the fretboard) is like one leg of a tuning fork — it’s resonating alongside every other part of the guitar and influences the motion of the strings, while it is simultaneously influenced by the motion of the strings. This said, the audible effect is very small on an acoustic guitar as there are so many other parts such as the body design and woods, which play a dominant role. In fact, the sound of the fretboard is often such a small influence that few players will be able to perceive the differences between woods. For something like a solidbody electric guitar, where the body resonance is a smaller part of the sonic soup than an acoustic, the sound of the neck and fretboard take a slightly larger role in what we players get to hear.

I own several Taylor guitars and love them all, including the 914ce. I play fingerstyle and singer/songwriter music such as Nick Drake and John Denver. I just recorded a song with John Denver’s closest family member. I also wrote a song for a new movie production in the UK.

These are unlikely and improbable events for a burned-out hillbilly lawyer who is struggling to stay alive due to severe Long Covid. Nonetheless, I practice and play for eight to nine hours daily. The sound of the Taylor guitars alone affords solace and refuge from all of life’s distractions and noises. I’m grateful to you for building such excellent-sounding acoustic guitars.

At 68, I’m probably too old to be a part of the music industry. However, I do have a good recording studio in my home.

My question relates to buying a “go-to guitar” — the best acoustic sound for recording and, if feeling better, playing for others. This will probably be my last purchase, but I want this to be my favorite-sounding guitar that could only come from Taylor. If I felt better, I would simply go to various dealers and play these good-sounding guitars. What guitar do you think is your best acoustic guitar for the purpose I just mentioned? I’m aware that much of this is subjective, but I love the bright sound of a Taylor, and I want to get the best. For the record, I’m actually a much better guitar player than I was a former prosecutor, judge and trial lawyer. Thank you for your consideration. Read Answer

Bobby, I’ll start by saying 68 is not too old to be part of the music industry. When you’re playing music, age isn’t as important as in something like playing sports. Your question — which is the best-sounding guitar we make for recording, and for playing with others? — is hard to answer. All of them. I’m not really joking. Each of the guitars we make works great in front of a microphone or amplified through a pickup. Lots of musicians will record with both. For a bigger, strumming-type sound, the 618 is a winner. For an articulate and balanced sound, one of our Grand Concert body guitars would be the answer. For a general-purpose guitar, a Grand Auditorium guitar with a cutaway, such as the perennial favorite 814ce, is a clear winner, or one of our Grand Pacific guitars. One model I turn to often is our Builder’s Edition 614ce. That guitar sounds like magic in front of a microphone. The combination of clarity, linear response and physical comfort makes it one of my favorites. One last point: For a change in sounds on your guitar for a particular recording, consider trying a different style of strings in the same gauges. It’s remarkable how big a difference in sound you can enjoy when you switch from phosphor-bronze to something like D’Addario’s Nickel Bronze, Bright Bronze or even the seldom seen Flat Tops, which are a secret studio trick for those who enjoy the kind of acoustic sound made by Nick Drake.

I often play Celtic music in DADGAD tuning and have a 2005 mahogany/cedar 514ce tuned this way. I have used light strings for years and now use Santa Cruz strings specifically for this tuning. The basses are powerful, and I really like this, but it is not very comfortable.

My point is this: A 12-fret guitar would be perfect, but I like to have a sound with powerful bass and good string tension. What solutions can be adopted, and which formats are most suitable for having a powerful sound and at the same time a comfortable guitar like the GC with 12 frets? Would it make sense to think about a Grand Auditorium with 12 frets? Read Answer

Massimo, I like playing in DADGAD too. The mahogany and cedar wood combination on your guitar is a nice choice for that tuning. If I understood your question correctly, you are looking for a more balanced handfeel from the strings when playing with this tuning. One aspect of this tuning is that you are loosening the tension of a few of the strings. Using a shorter scale length as we do on our Grand Concert, guitars will tend to make the strings feel looser still. I recommend a simple trick first — try stringing your 514ce with a light-gauge set of strings, then gauge up the low D and the high A and D with strings from a medium set. The slightly larger gauge will balance out the handfeel. If I misunderstood your question and the guitar’s overall size is what feels uncomfortable, I’d certainly seek out a 12-fret Grand Concert such as the 812ce and see how it feels to you. You might find that the low-end response from that guitar complements the sound of DADGAD tuning in a way that pleases you.

I’ve always been a great fan of your guitars — I went through a G.A.S. [Guitar Acquisition Syndrome] phase and now own a number of them. I have 14-fret models, 12-fret models, various scale lengths, etc. When I go from one guitar to a different one, I find myself playing very poorly for a while until I get the feel of something different from what I played last. Is this normal, or am I simply a poor guitar player? When I’m in the groove, I can close my eyes and have an out-of-body experience playing. I’m finding that harder to do when I’m switching guitars all the time. Read Answer

Dave, practice makes perfect. But seriously, the truth is that most musicians feel exactly what you are describing. There are so many subtleties in each guitar, especially the different ones you own, and those unique characteristics are probably why you have such a variety. It’s common for a player to need some time to get to know or get reacquainted with each one. To me, that’s part of the fun of playing guitar — exploring what each instrument can offer you. It would be really boring if I picked up each guitar and played exactly the same thing, and they sounded and felt exactly the same. Variety is good. Embrace it.

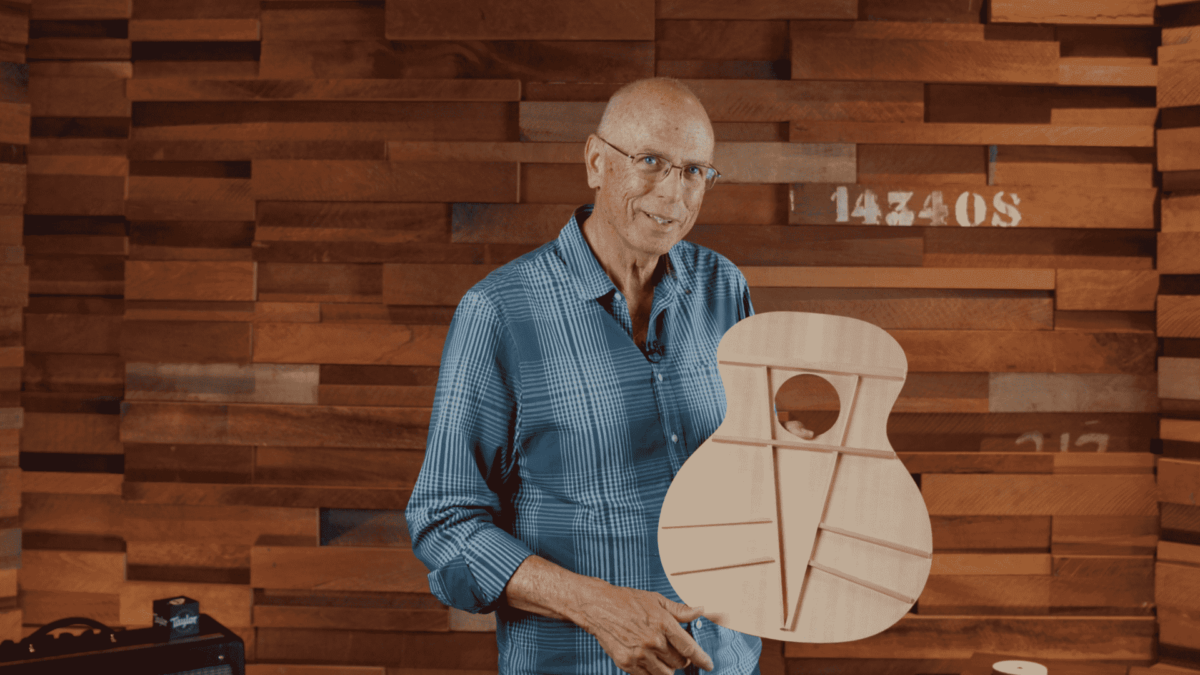

I have a GT Urban Ash guitar as well as Grand Concert and Grand Auditorium 500 Series Taylors. I am impressed with the C-Class bracing [on the GT]. Has C-Class been tried on a Grand Concert-sized guitar, and if so, what was the result? Read Answer

David, I love those GT guitars too. I’ll tell you a secret: Yes, I’ve tried adapting the C-Class idea to the size of a Grand Concert guitar. It wasn’t a big surprise to find out it can sound quite good. I do really like the C-Class-style architecture we are using on a lot of Grand Concert guitars. In reality, both of those designs originate from the same basic structural thoughts — one symmetric, one asymmetric in form, which lend different characteristics to the voicing. You’ll see more of these designs spread into a wider variety of our guitars as time goes on.

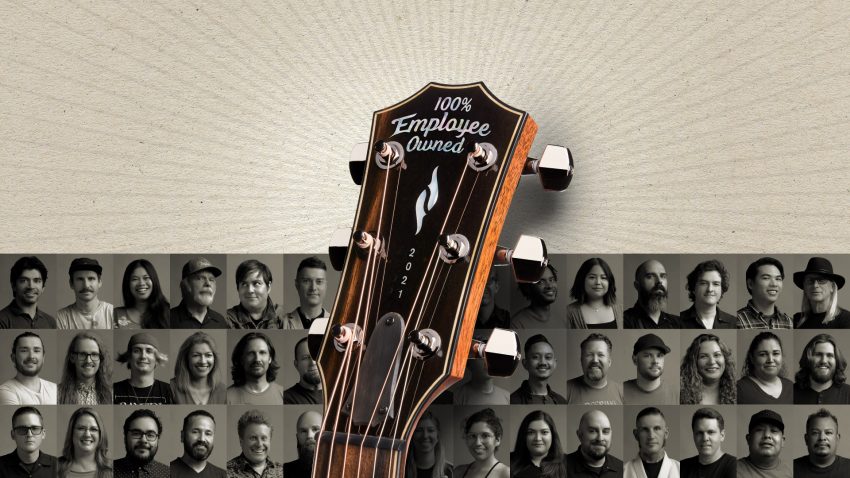

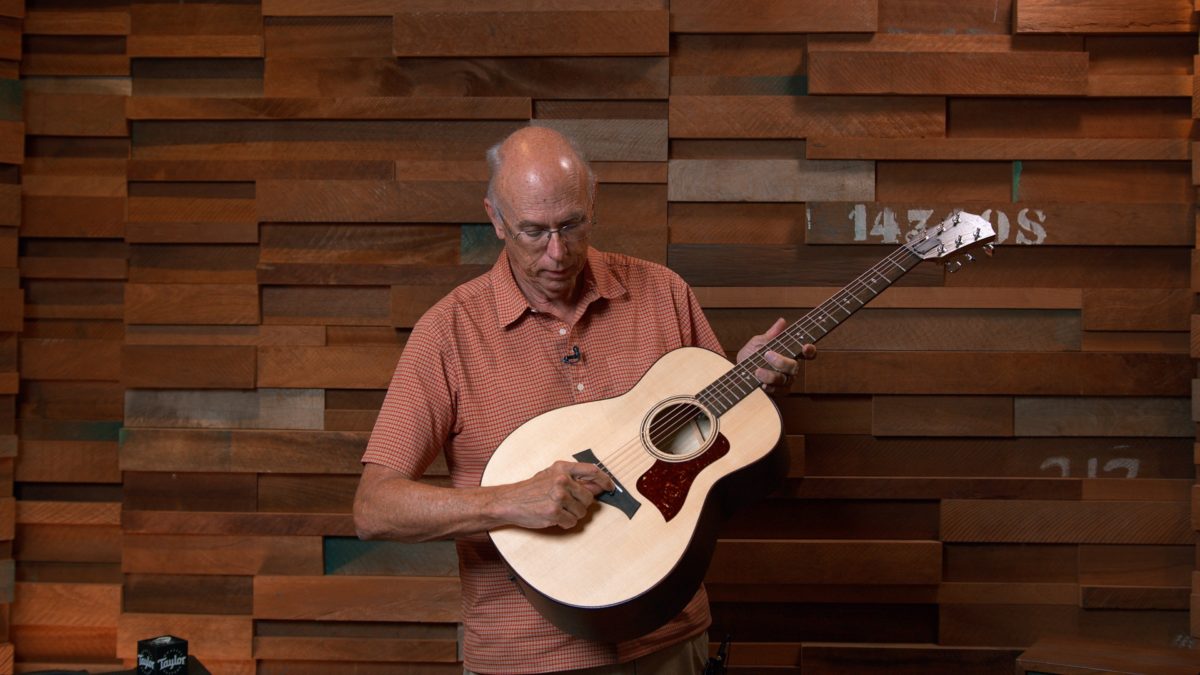

I have been a happy owner of a Taylor for a long time, but I’ve always wondered, what is the name of the shape of the headstock that Taylor uses? Sometimes I seem to see, with a lot of imagination, a mountain — perhaps it reminds me of the greatness and quality that distinguishes these guitars. What is the history behind the design of the headstock? Read Answer

Antonio, I wasn’t around back when that headstock shape was designed, but years ago during my pre-Taylor guitar life, while making a replacement neck for an early Taylor guitar, I noticed that the three scoops on the crown of the original headstock were a perfect match for the front roller of my belt sander. I recall thinking to myself, “I’ll bet this is where the shape came from.” Fast forward another 10 years, and the story I heard went something like, “We had this belt sander in the shop….”

Bob: Your guess was spot on, Andy. To add more color, this shape was what Sam Radding used at the American Dream shop, which was the little shop Kurt and I bought from Sam and started Taylor Guitars. We inherited Sam’s headstock shape from him, and he was clever enough to use the roller on the end of the belt sander to grind three scoops. The curious thing is that there are precious few possible shapes left in the world to use, and this one not only looks good but is unique. If you asked me to design a headstock shape now, I’d be at a loss. No matter what I would draw, it would be reminiscent of something that already exists. A nice feature of Taylor guitars over the years is that all of our trade dress is unique and our own, and I’ll declare again that this is quite difficult to do now. By the way, it has no formal name.

Have you ever made a GS Mini with a cedar top? Might that make a good limited-edition model? Read Answer

Pedro, yes, I have built a GS Mini with a cedar top. It certainly is a cool guitar, and at some point, we might make some like those. Finding great Western Red cedar has become increasingly difficult, which is a shame, as I do love using it as a guitar top. Cedar is like many woods in that the future will see us making more and more use of alternative sizes of wood in the form of multi-piece tops and backs to yield the great-sounding guitar parts we love working with.

Why are headstocks on 12-fret guitars usually slotted? I played a 714ce 12-fret in a shop a while back and absolutely loved the rich sound of the 12-fret versus the already amazing 14-fret 714ce (my brother has one). So, I think a 12-fret guitar is somewhere in my future. There was an all-koa limited-edition model a few years back that was 12-fret, yet had the traditional headstock, and it really looked fabulous. I’m also in love with the Gotoh tuners on my main guitar (2009 GSce-C Fall Limited) and would always choose those as an option if I could. Do you plan to offer more 12-fret guitars with a traditional headstock in future, or is this something that can be built to order? Read Answer

Chris, the tradition of a slotted headstock goes a long way back in guitar history to a time when most guitars used slotted headstocks and necks, which joined the body at the 12th fret — a holdover from an even earlier fretted-instrument tradition. Part of the continuation is simply appreciation for that tradition. The guitar-building nerd side of me will also point out the angle the strings make as they pass over the nut is radically different on a slotted headstock, putting a tremendous amount of pressure against that part compared to a solid headstock. That tends to influence the feel of the strings under your fingertips in the low position on the neck. Looking to the other end of the strings, we see the bridge is attached to the top in a more central position, which tends to be a more flexible part of the guitar’s top. Some players will notice that this gives a slightly slinkier, looser feel to the strings near the saddle where you’d strum. The loose and friendly articulation handfeel is a nice complement to increased crispness of the fretting handfeel. That’s a very subtle aspect, but for those of us who examine things closely, it’s something that contributes to the feel of the guitar. We do occasionally build 12-fret guitars with solid headstocks. That’s another perfectly functional design choice.

I’m a musician who works in manufacturing, and I’m interested in large-scale manufacturing quality control with acoustic guitars. What unique things have you done over the years to maintain the highest levels of quality control across two facilities in two countries when you’re constantly innovating your products? Read Answer

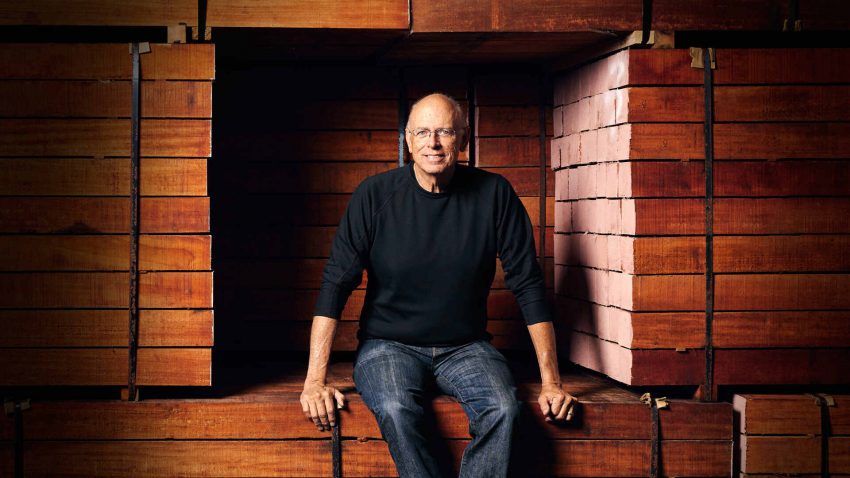

Luis, a list of individual processes, methods and tools we use to manufacture our guitars and maintain quality would fill a book. Or a whole collection of books. In my opinion, one of our keys to maintaining quality at a large scale is we develop and create our tooling and manufacturing processes here in our factory, so we have complete control over each tool, fixture, template and part, and how they work. This is a natural continuation of the approach Bob Taylor adopted right from the beginning of his guitar-making life — spend the day making guitars and spend the night making tools to do a better job making tomorrow’s guitars. Layer on top of this a dedication to constant training (and retraining). For icing on top of the cake, our factories in the U.S. and Mexico are in close proximity to each other — about a 45-minute drive. This proximity allows us to maintain continuity between our two very connected operations.

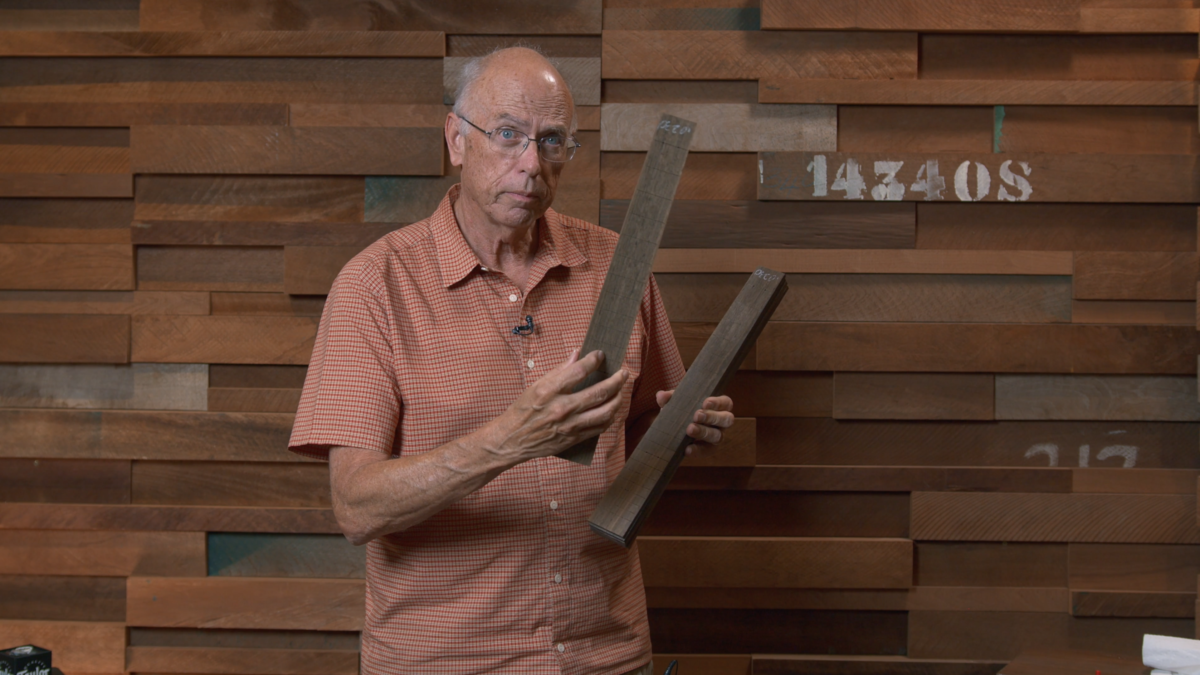

The custom Taylors I’ve seen have gorgeous tonewoods and grain patterns. What factors guide the selection and grading of tonewoods for limited-edition and custom-shop guitars, and how, if at all, does this process differ from standard production models? Read Answer

Mia, we love great wood. The woods we use for the guitars in our regular portfolio of instruments are carefully sourced and graded for the structural, tonal and visual characteristics needed for each model. The woods we select for custom instruments, limited- or special-edition guitars are often just that: they’re special in one way, shape or form. Often, these are woods we can’t source on a consistent basis but found as a great batch of material to build some fun guitars with. Other times, the wood selected for a custom guitar might be an often-used species but has properties that stand out and warrant being set aside for a different use. We’re guitar makers —we love a beautiful-looking/sounding piece of wood as much or more than anyone. And we’re thrilled to use them and enjoy the process and result.

I love some of the urban tonewoods you’re using from California. With such a wide range of tonewoods available, what’s the most challenging wood you’ve worked with, and what unique difficulties does it present when making a guitar? Also, are there any tonewoods you absolutely won’t use despite their musical virtues because they’re too challenging to work with? Read Answer

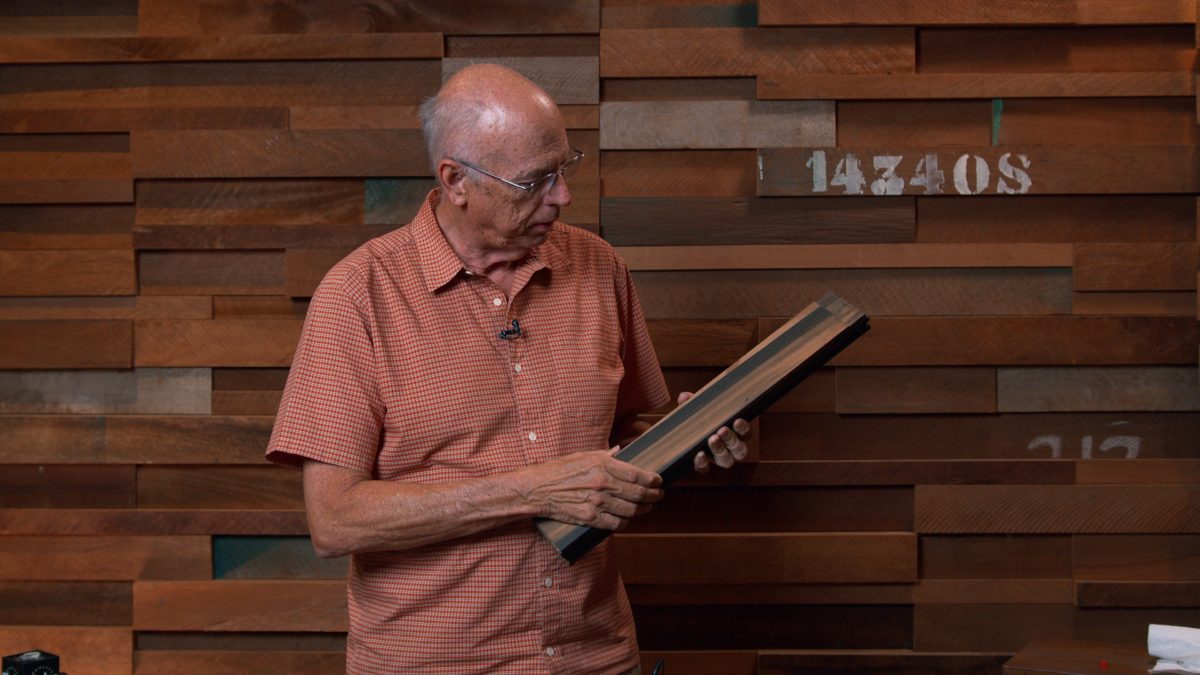

Nick, there are a lot of challenging woods out there, including some we use often. Ebony would be near the top of the list. It’s a serious challenge to dry and use due to its density and other physical characteristics. We use it for a lot of guitar fretboards and bridges each day, and you would probably be surprised how many steps a fretboard needs to go through before it is dry, stable and ready to use on a guitar. Cocobolo is another very challenging wood to work with. Often, the practical characteristics of a wood are what make them usable or not for a guitar (or any woodworking project for that matter). The types of questions I’d ask about a wood go something like this: Can the wood be sourced, transported, dried and seasoned without warping or cracking? Can it be glued, sawed, planed, sanded, bent, finished? Is it stable enough to serve a musician in a reliable way? Some woods perform well in all of these regards and become favorites. Others pose a challenge in one and often more of these areas and need special care. I’ve come across a few wood species that are so difficult and unpredictable in their behavior and working characteristics, I simply don’t try. Even if I might get one good guitar part from the wood, it may not perform reliably for a musician over time, warping or cracking after the guitar is done. Those woods don’t belong on a guitar.