You might want to pour a cup of coffee because this is a little longer than I normally write. I thought I’d use the introduction of the American Dream Series as an opportunity to talk about manufacturing.

For nearly half a century, I’ve been engaged daily in manufacturing, and I have developed some understanding on the topic. I think it’s safe to say that my experience, which started with me and a chisel and led to where Taylor is now, is probably more filled out than if I’d been a manufacturing engineer working for a firm, due to me being the one who has made the lion’s share of manufacturing decisions for us along the way and having to live with the consequences of my decisions. I know what it’s like to work nearly alone and to have well-developed operations in four countries, each with different laws, languages and cultures.

I’m pleased that our company has grown to be successful and kept everyone’s interest in mind, from customers and employees to vendors and shareholders, and to the community around us.

The Different Costs of Manufacturing

All companies sell a product while trying to make a profit through a fair balance between their costs and what they receive upon a sale to their customers. As for the individual employees of any company, we all want to earn the highest salary possible for ourselves. But what happens when we each want to pay the lowest price for the things we buy for ourselves? We all look at competitive products, and often buy products that are made in places where costs are lower, which usually means lower wages. When wages are lower in a different country, the other supportive costs can also be lower since their infrastructure carries lower costs as well, all based on the equilibrium of their local wages and economy.

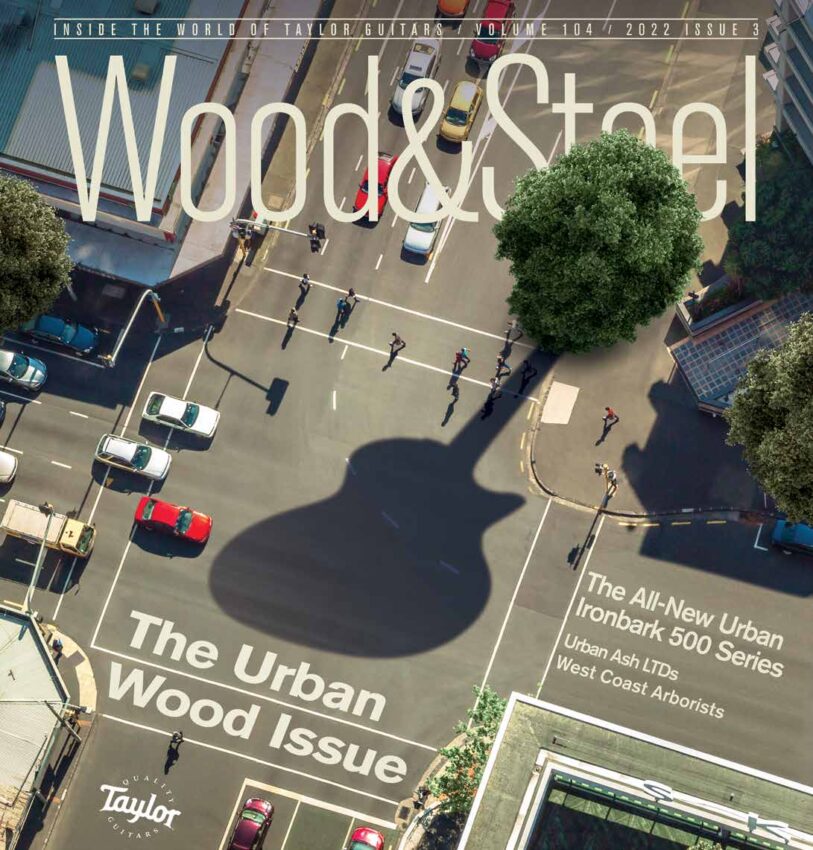

A good current example of cost difference is our Urban Ash guitars, made from wood we get from here in Southern California. Some people have asked how we take a “free” street tree that was going to become firewood and make guitars that cost as much as guitars made from traditional woods.

Simply put, it’s because the costs are higher, and nearly all those costs go to people living here and doing the work to that tree. Well-paid Americans safely remove the trees 10 feet from a road or house, transport them, saw them, and transport them again, all with American wages, on domestic roads, paying taxes, complying with OSHA standards, earning health benefits, etc. In other words, it’s you or your neighbor who is being paid to convert that tree into guitar wood for us. If we wanted only the cheapest wood, we could find places where it’s the opposite of the attributes I just described, but if you want to do it here, it costs more.

Cross-Border Localism

Buying locally is an idea that interests many of us in our own home towns. But it shouldn’t end with food or independent retail shops. I admit that you can’t always get what you want locally, but we might all want to appreciate the work our neighbors do, and if it’s possible to support them, it comes back around to them supporting us.

Even so, our guitars are made in two different countries. When I leave my house in the morning, I can turn left and be at our American factory in 20 minutes. Or I can turn right and be at our Mexican factory in 40 minutes. This is somewhat accidental that we are so well-poised to operate in two countries.

“I can turn left and be at our American factory in 20 minutes, or turn right and be at our Mexican factory in 40 minutes.”

Here at Taylor, we understand cross-border relations from a real-world, workaday perspective, as well as a family and friend perspective. Both factories operate as one company, even with two languages and two cultures. That’s easy from our proximity to each other. We understand and enjoy each other. It’s an advantage for us as makers and you as players that we are able to make guitars across a wide range of prices, and to provide jobs in both the United States and Mexico.

We didn’t move our U.S. production to Mexico. Rather, we started fresh there, making guitars we would not have been able to make here in El Cajon. I am content with the ethics of us expanding across our border. In fact, I’m proud of it. There are over 500 people in Tecate who have good jobs building guitars that otherwise wouldn’t exist.

There is something elusive about making a very good guitar, and many factories around the world haven’t figured out the secret sauce yet. We don’t think of ourselves as having secrets (we tend to share), but we’re dedicated to doing the things needed in order for our guitars to be good enough for players to notice the difference. Having our twin factories allows us to do that rather than outsourcing our lower-priced products to other companies across the ocean.

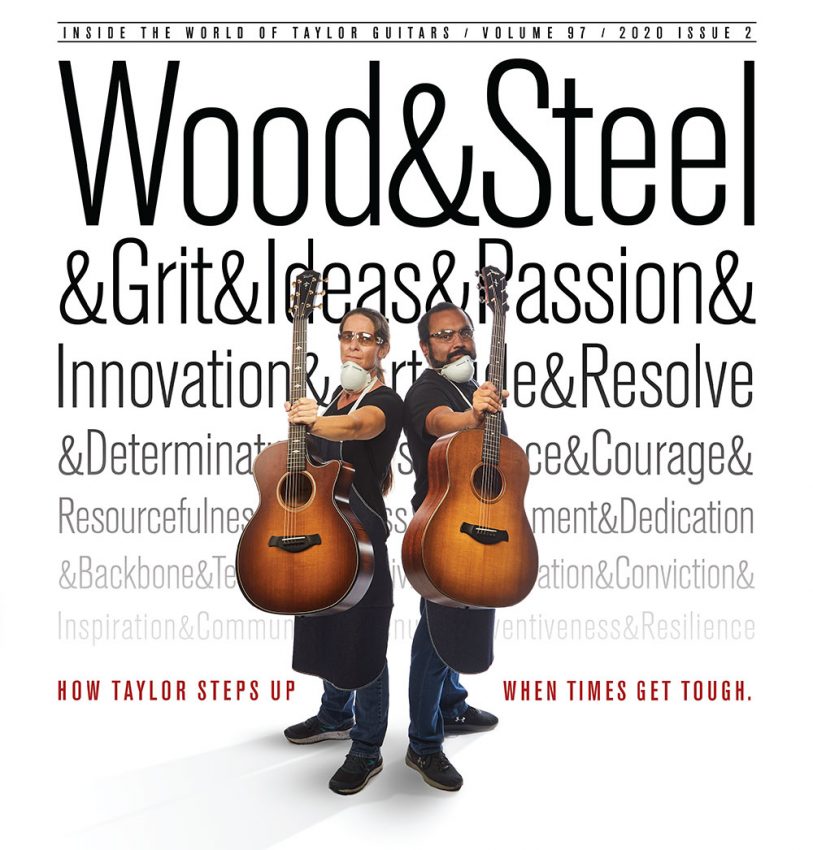

Adapting to Upheaval

When COVID-19 locked down people and businesses all around the world, we found ourselves with a closed El Cajon factory, then a few weeks later, a closed Tecate factory. After some time, El Cajon began to open slowly while Tecate stayed closed. We asked ourselves, “What would happen if we couldn’t deliver our Tecate-made models into the market?” We knew we wouldn’t have any hope of delivering GS Mini, Baby, Academy, or 100 Series guitars. They’re just not possible to make here. The 200 Series might be possible, but the tools and systems are there; we simply don’t make that guitar here. We make solid-wood guitars here in El Cajon.

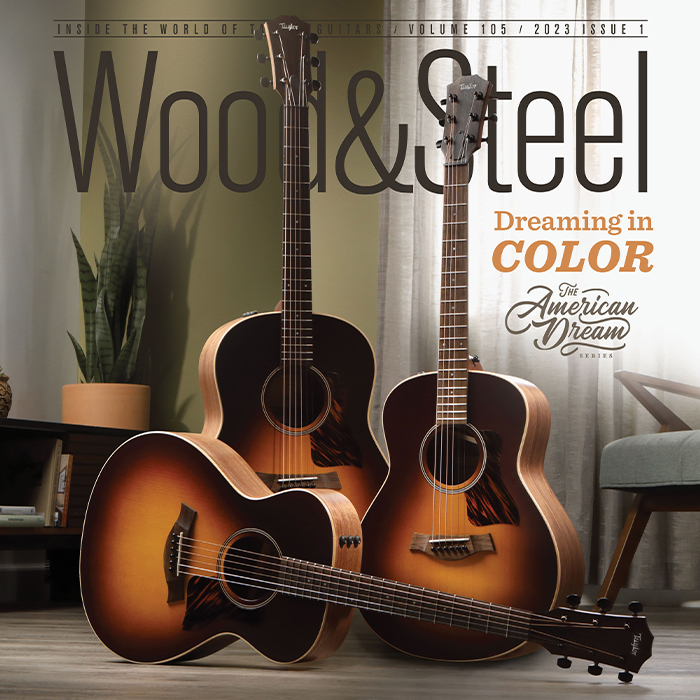

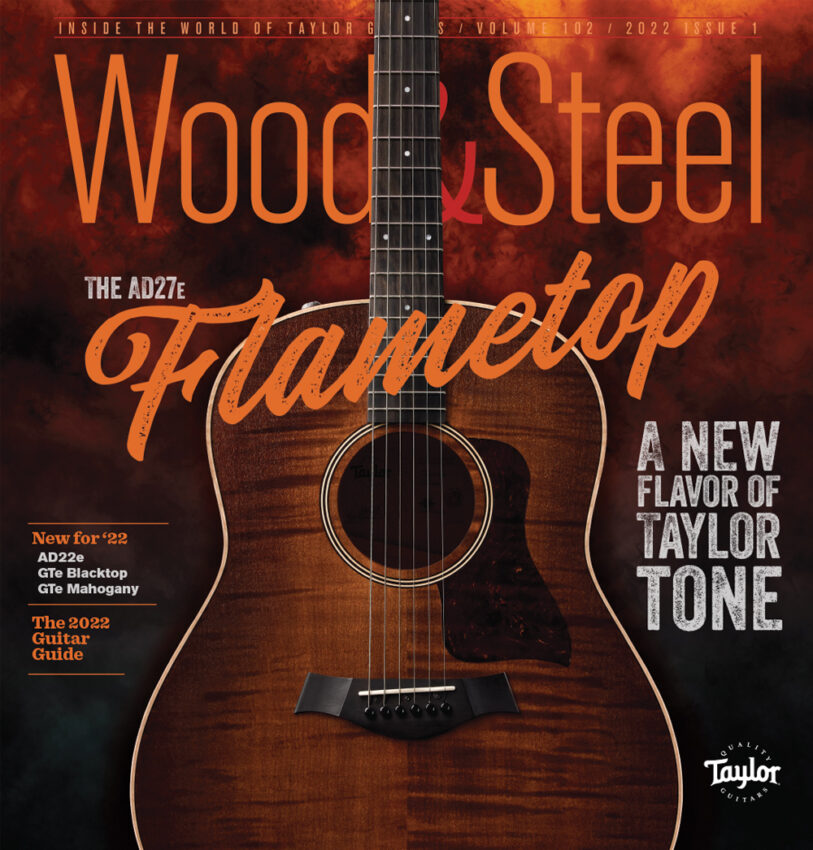

So we began to form the idea of what became the American Dream Series, which combines some special building techniques along with using normal tonewoods that we’d set aside over the years due to some cosmetic attributes, odd sizes, or species we don’t currently use in our lineup. We like to say that we’re cooking with what’s in the refrigerator. The event thrown upon us this year caused us to think and act this way.

Tecate seemed far away during those months, but soon we realized we have a legitimate presence there and that we are part of that city, just like we are here. We quickly converted gig bag sewing into mask production to help the local health care workers. We got permission to run that small sewing line during the closure. Eventually the lights started to come back on in the other areas of the factory. We began working with governmental labor, economic and health officials to outfit our factory for an eventual safe re-opening. This was the test of a lifetime of our relationship with the city and country we are in.

Meanwhile, the American Dream Series was born here in El Cajon. We didn’t want to wait to see what might or might not happen in Mexico. A lot of thought went into this guitar, and we moved quickly to break down mental and physical barriers so we could produce the guitar. People started trickling back to work in El Cajon. We felt optimistic and creative. This guitar was a triumph for us during this time.

Move forward to today and our employees are back to work in both places under such strict social distancing that we have to use 24 hours of every day and all 7 days of the week to get our work done. But we’re healthy and safe, and our livelihoods are restored. Our dealers are thrilled because their livelihoods are better, and customers have rediscovered the joys of homemade music. We’re shipping, dealers are selling, and you’re playing. It’s all good. And these thoughts I wanted to share are meant to relay that stuff comes from places that make stuff, from people who work in those places that make that stuff. Many of those people are you, your neighbor, your family or me. We all work to provide something that is sold, and we all buy things that others make. It’s symbiotic. You support us, we support you. This year has caused many of us to think about things — what’s good, and what’s not. I think we can all agree that music is good.