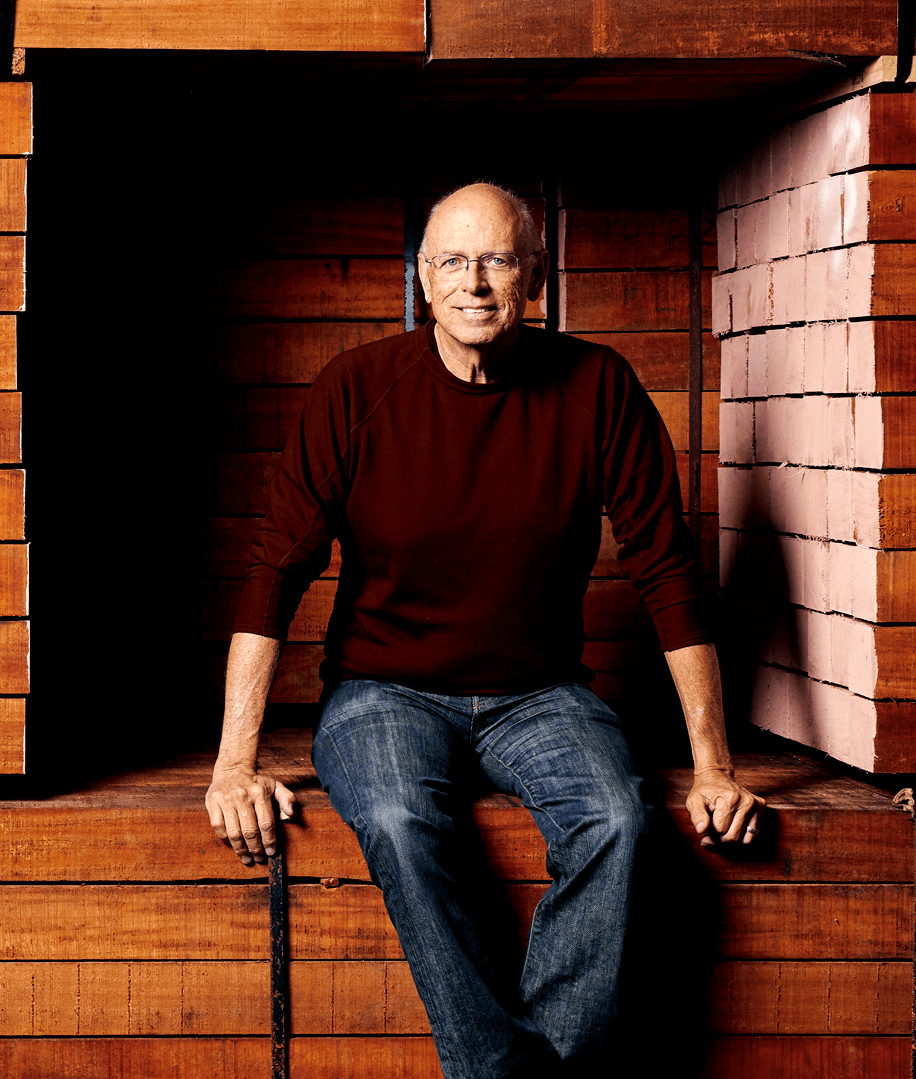

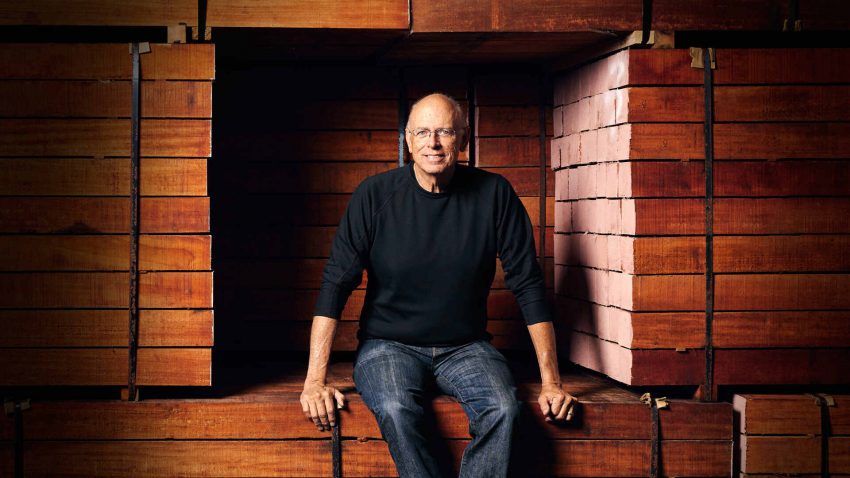

This is a good year to look back on what Bob and I have lived through and accomplished since we started the business in 1974. Usually, Bob and I look ahead at the goals and projects we have planned; looking back isn’t much more than an acknowledgement of recent challenges and successes. But it’s not every year you get to celebrate your 50th anniversary in business, as we are in 2024. So, we’re going to spend some time this year recounting our history, good and bad. Success and horror stories. Smart things we’ve done, as well as our blunders. What it was like to start a business when I was 21 and Bob was 19, and to grow up learning life and business lessons. And now being retirement age and no longer owning the business, but still helping direct it from an advisory and board level.

When we bought the American Dream guitar shop, we just wanted to make guitars, have a company, and hopefully be able to make a living. We didn’t think beyond that, and how could we? We had no perspective. We just assumed we’d do some repair work, make some guitars, make a few bucks. That lasted a few months. Then we had to get more focused and disciplined, strengthen our work ethic, and start the long process of understanding how to be profitable and generate stable cash flow.

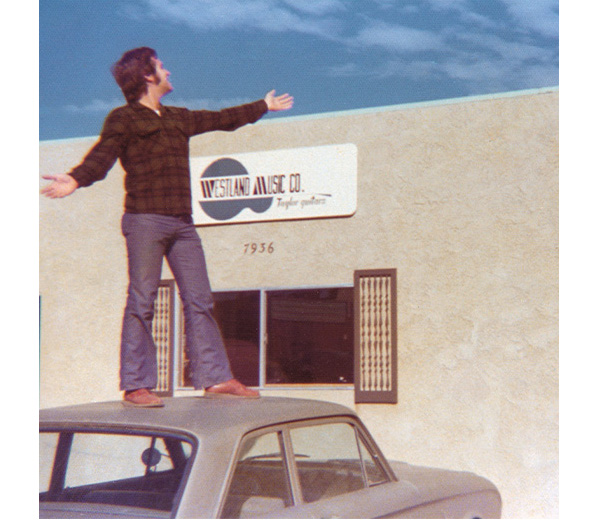

A proud Kurt Listug atop his Ford Falcon in front of the shop, circa 1974. The sign features the first logo for the Westland Music Company, later changing the name to Taylor Guitars in 1976.

We had a lot to learn. How to dry wood properly. How to apply a great finish. How to get work done in a consistent fashion. How to make a budget. How to sell guitars. How to advertise and promote. How to hire and manage employees. How to manage cash, pay ourselves and pay our taxes. How to continually improve every process to make ourselves better.

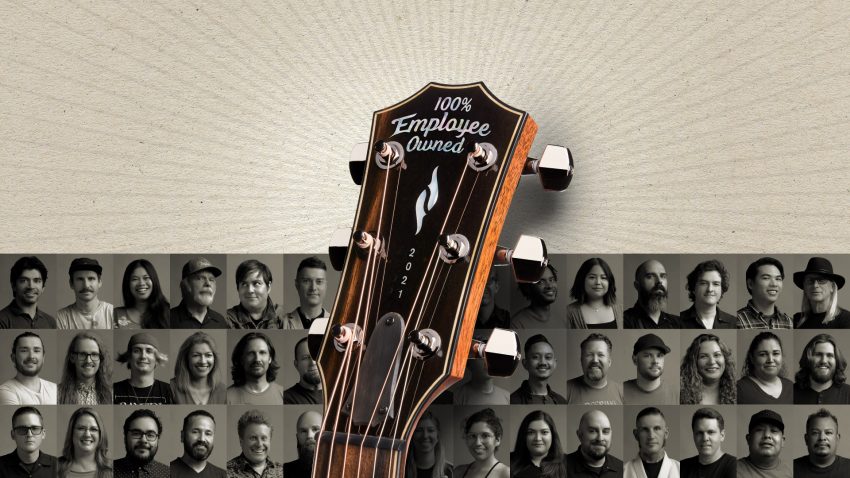

As we grew through the years, our purposes expanded to include everything we touched. To treat our employees and vendors well. To be a good steward of the environment. To help our resellers be successful. To set a high standard and continue to elevate in everything we do.

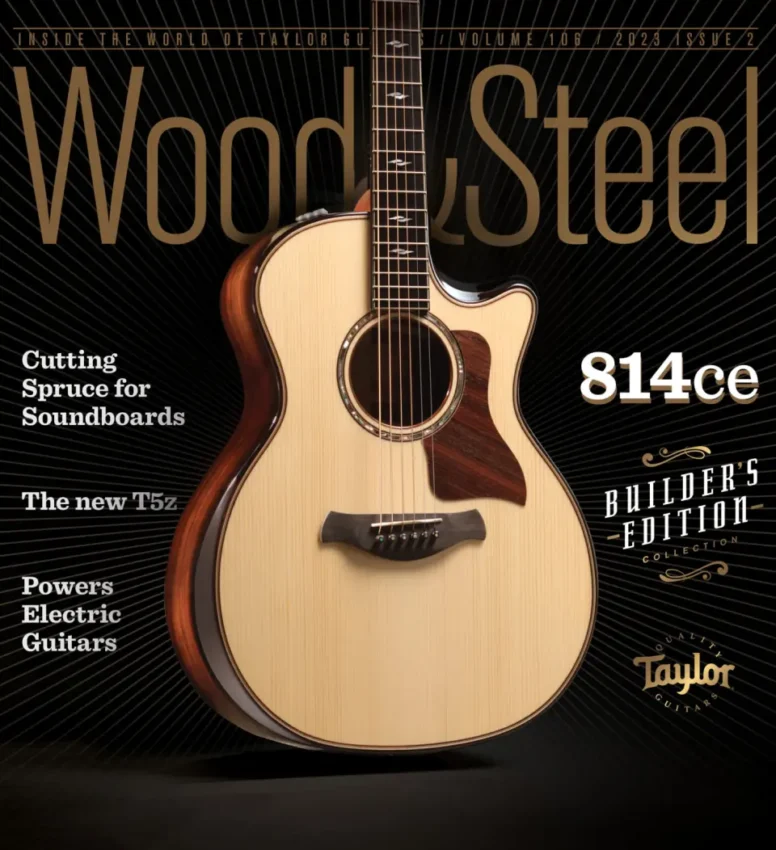

Fifty years ago, we had no idea what the journey ahead would bring us. Indeed, it brought us incredible challenges, great successes, rewarding experiences and lifelong friends in the process. And like a lot of older people, we have a lot of good stories to share. We’ll be sharing these with you this year, through Wood&Steel, social media and the Taylor Guitars 50th Anniversary Podcast Bob and I have been recording over the past year.

Many thanks to my lifelong partner and collaborator, Bob, my family and my wife Jenny for their support, all our past and present employees, the many music shops that sell our guitars, and, of course, all the guitar players around the world who have enabled us to pursue our dream.