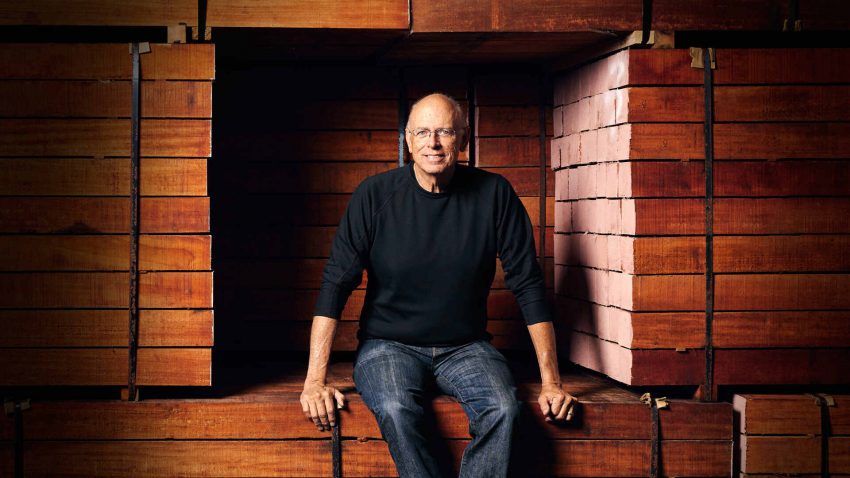

It’s been an exciting time for us at Taylor Guitars. Last year marked our 50th anniversary, and we celebrated with a yearlong rollout of commemorative limited-edition models inspired by player favorites from recent years. We also honored some of Bob Taylor’s classic designs with the launch of our Legacy Collection, which was personally curated by Bob himself. (The collection continues this year as a dedicated offering within our guitar portfolio.)

But innovation is in our DNA, so as Taylor rolls into its next half-century, we’re back to pushing the envelope and thrilled to unveil some new, radically different guitars to kick off 2025. They’re part of what we’re calling our Gold Label Collection. Before we get to the guitars themselves, a bit of backstory will help set the stage.

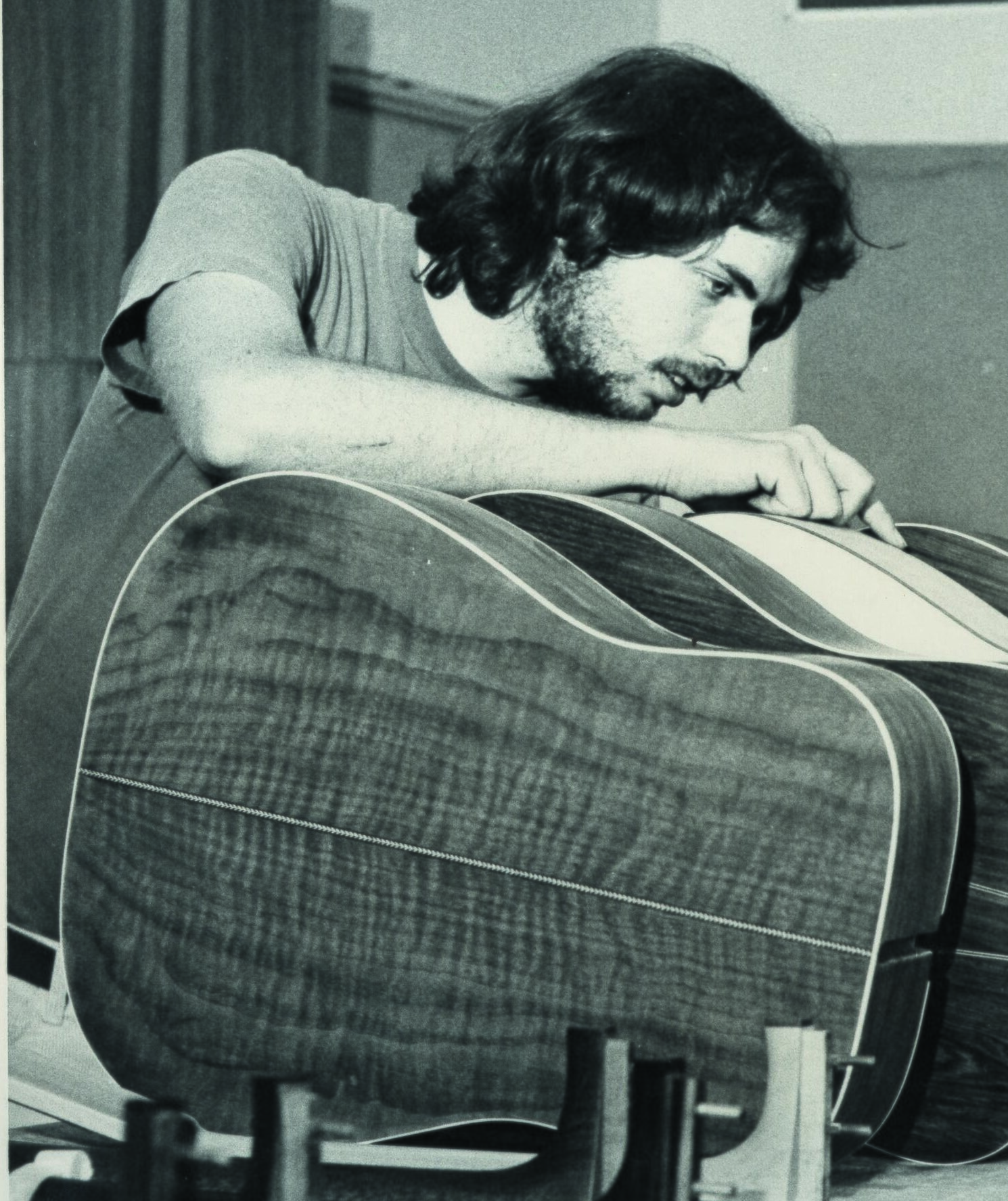

Building on Bob’s Foundation of Innovation

For more than a decade now, Andy Powers has been Taylor’s innovator-in-chief, and he’s done plenty of innovating since Bob Taylor handed him the guitar design reins. While the guitar world has come to expect new designs from Taylor, Andy understands the core attributes of a Taylor guitar that people continue to appreciate.

“Many of the innovations Bob brought to the guitar world have served players in realistic, practical ways which helped make our guitars popular,” he says. “Like a playable neck. Consistent build quality. Reliability. Serviceability. We always want to preserve and build on those attributes.”

How Bob Defined “the Taylor Sound”

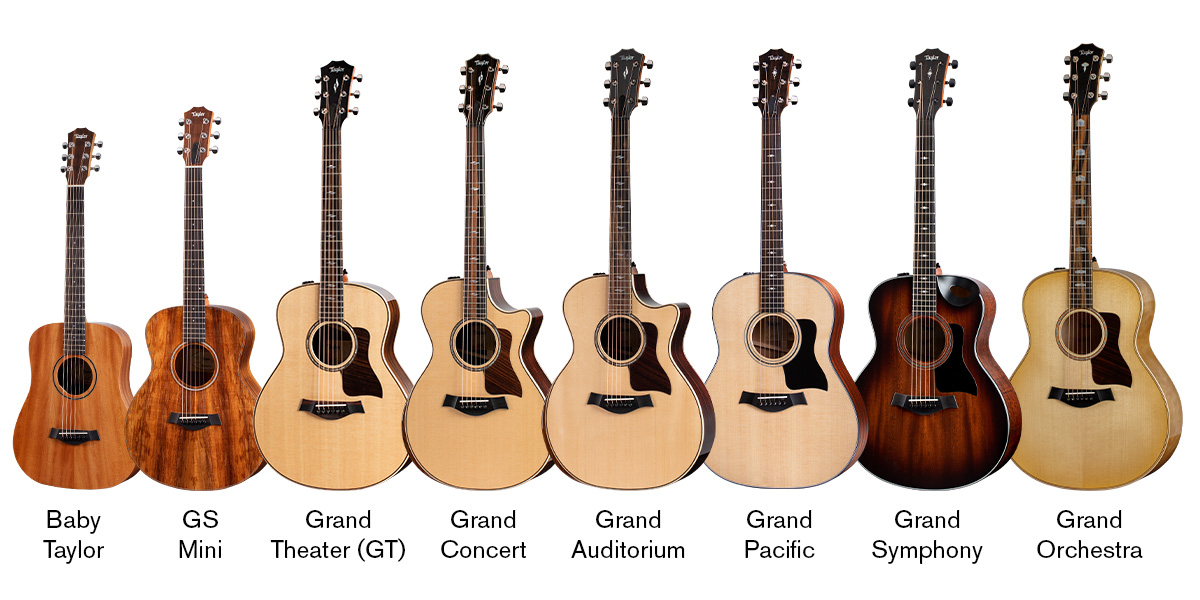

Bob’s guitar designs also introduced distinctive sonic characteristics that became closely associated with a Taylor guitar, embodied most clearly in the flagship Grand Auditorium body style he introduced in 1994. When people talk about “the Taylor sound,” they’re often referring (whether knowingly or not) to the Grand Auditorium, with its tonal clarity, articulation and balance, and its lack of boominess in the low end — properties that gave the guitars great utility for recording or live performance because they were sonically well-behaved.

How V-Class Bracing Opened Up a New World of Tonal Flavors

People’s personal preferences around acoustic tone vary widely, like they do with food and flavors. Many players also can appreciate a diverse range of acoustic voicings. Andy understands this. In fact, prior to joining Taylor, his own expansive musical tastes as a player included other acoustic flavors not represented on Taylor’s guitar menu at the time.

That’s why, after becoming Taylor’s chief guitar designer, one of his goals was to expand the diversity of Taylor voices within the line to appeal to a broader array of player tastes. One area where he felt most constrained was in the traditional X-bracing architecture that had dominated the acoustic steel-string landscape for well over a century. To make greater strides, he felt he needed a to develop a new type of internal voicing framework.

After a couple of years of experimenting, that breakthrough came in the form of his patented V-Class bracing architecture, which Taylor officially introduced in 2018. Touted as a “new sonic engine” for an acoustic guitar, V-Class not only brought tonal enhancements like greater volume and sustain, but it also improved the pitch accuracy of notes all the way up the fretboard by helping the soundboard translate the string energy in a cleaner, more accurate way. This in turn created more harmonic agreement between notes and solved the chronic intonation issues that had long plagued acoustics.

V-Class earned industry awards and was loved by players and recording engineers. But the greater potential of V-Class was that Andy now had a powerful and highly adaptable voicing architecture that he could manipulate to dramatically expand the sonic palette of Taylor’s guitar line.

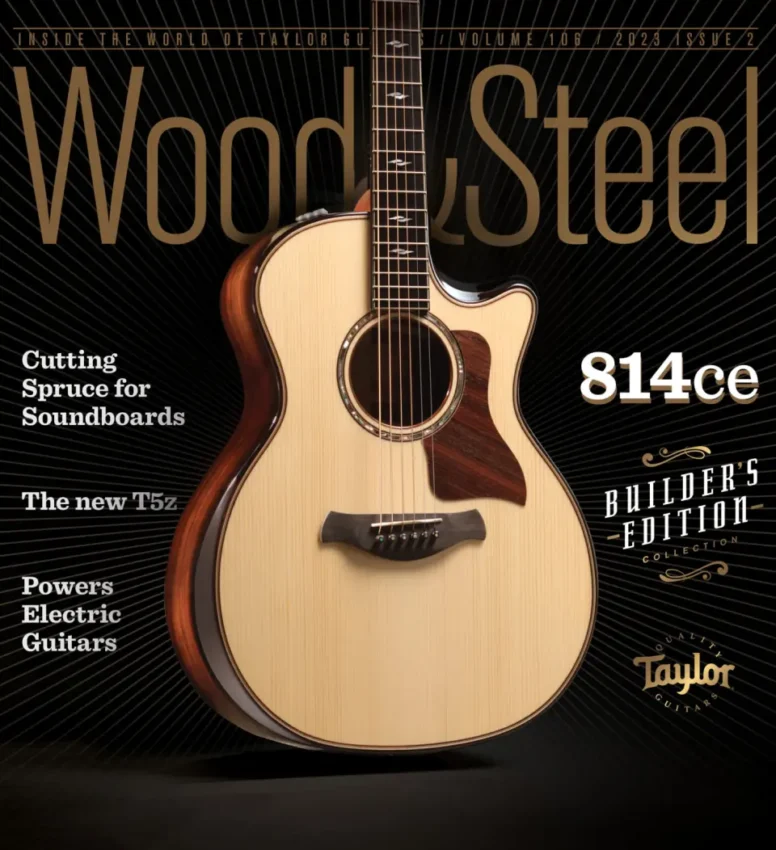

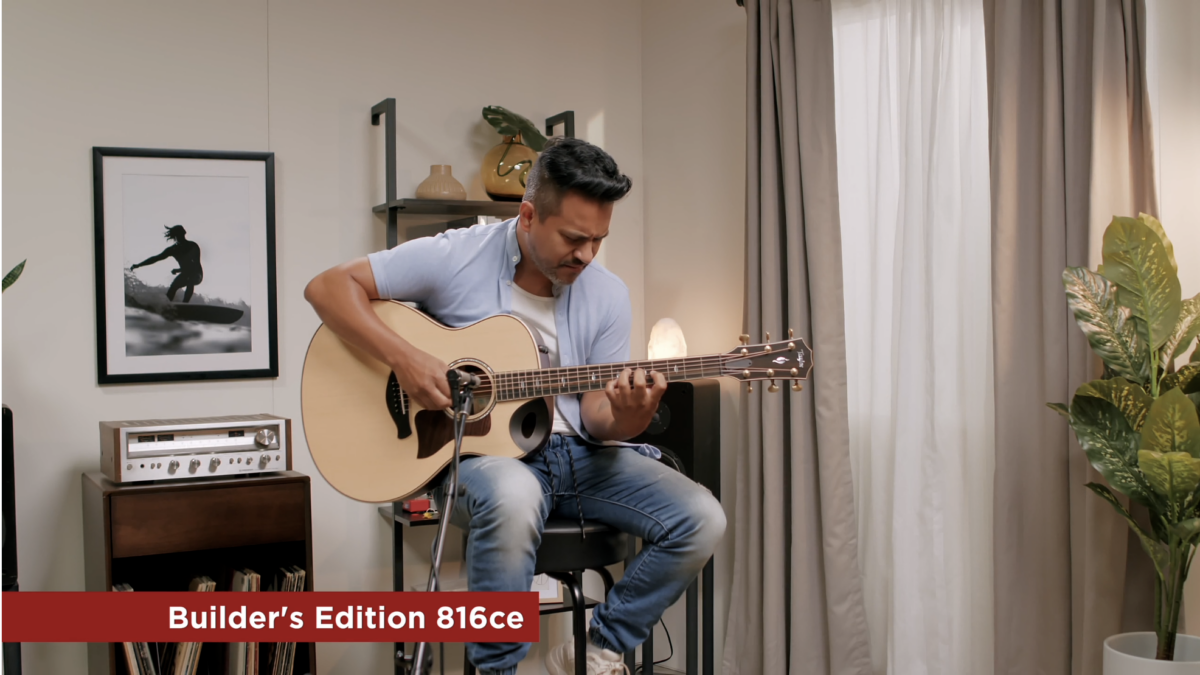

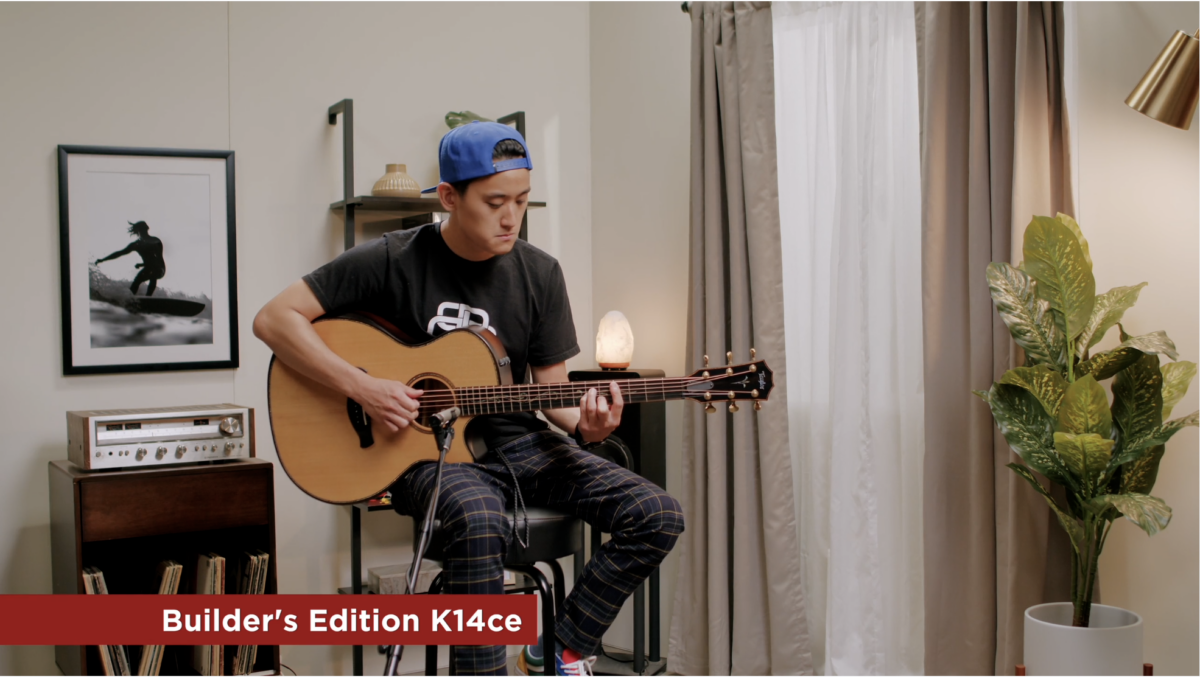

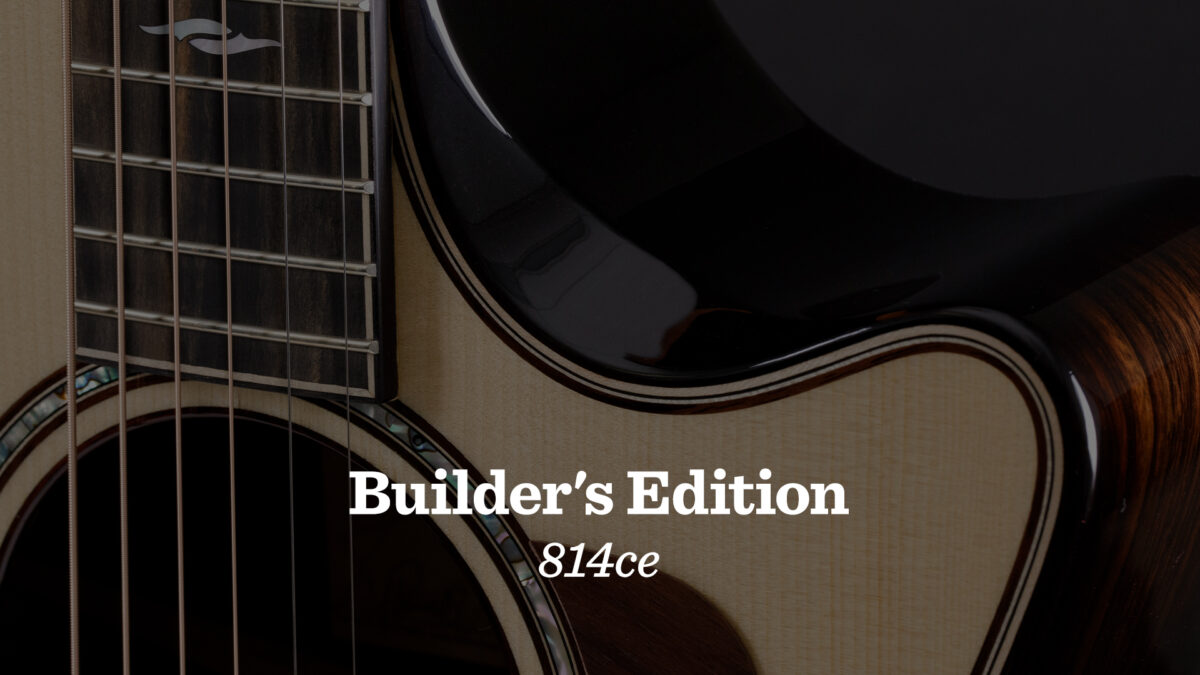

Builder’s Edition

An important design platform Andy used to introduce V-Class was his Builder’s Edition guitars. The underlying design concept was that there are two fundamental ways to improve a guitar’s performance: sound and feel. Where V-Class checked the sound box, Andy wanted to match that by leveling up the playing comfort of a Taylor, building on Taylor’s established reputation for playable necks with ultra-premium playing features like beveled armrests and cutaways, chamfered body edges and other ergonomic refinements.

Over the ensuing seven years, Andy has gradually expanded Builder’s Edition into a diverse collection of more than a dozen uniquely crafted models that each showcase a distinctive musical personality in both sound and feel.

The Grand Pacific

Another interesting design introduced via Builder’s Edition was a new Taylor body style: the Grand Pacific, a round-shoulder dreadnought. In the same way that V-Class helped “fix” some of the sonic shortcomings of an acoustic guitar, with the Grand Pacific, Andy specifically addressed some of the issues with dreadnought-style guitars, namely a lack of clarity in the low end.

At the time, the sound of the Grand Pacific was presented in contrast to the classic “Taylor sound” of the Grand Auditorium. Where the Grand Auditorium’s soundprint was a clear, vibrant, piano-like voice with precise, well-defined notes, the Grand Pacific delivered a warmer, more seasoned sound, with a rounder note shape that caused notes to blend together.

Yet Andy knew he was still just scratching the surface with V-Class. In fact, he already had a more radical design beginning to simmer on the back burner. But it would have to wait as Taylor pivoted in response to a pandemic, and then to design and roll out our 50th anniversary and Legacy models. Now, its time has come.

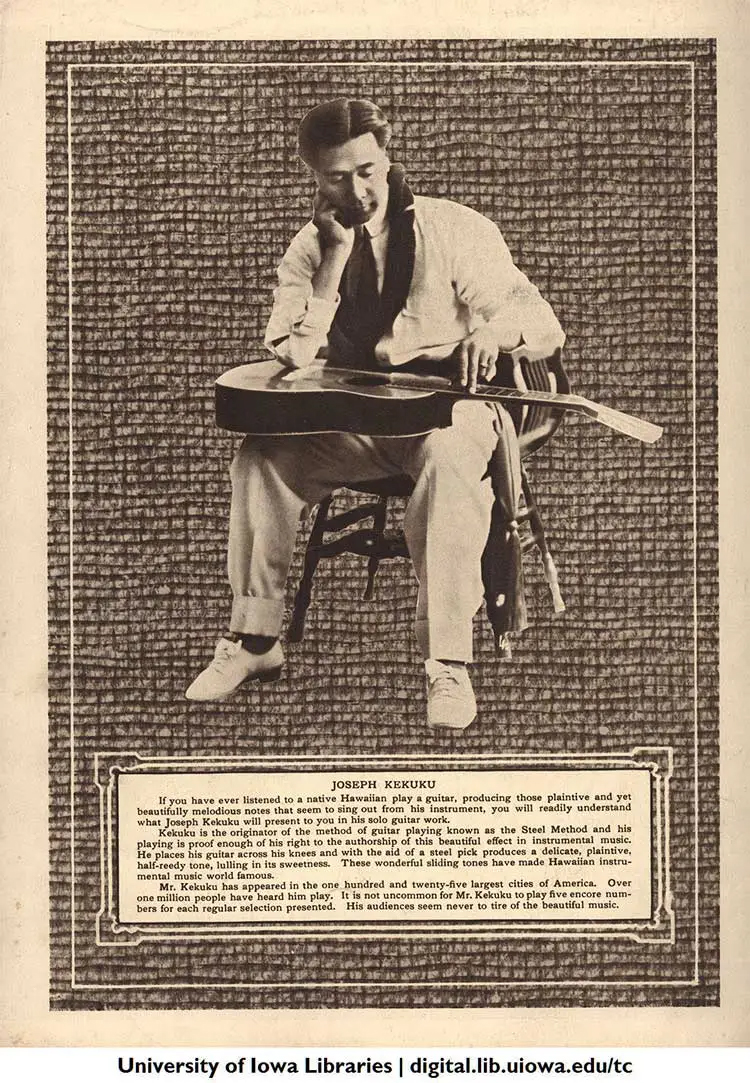

A New Recipe for an Old Sound

Andy’s sonic reference point this time around was a much older acoustic tone — specifically, the sound of classic acoustic flattops from the 1930s and ’40s, many of which he had played or restored as a sought-after repair person earlier in his life. He calls it a “heritage” sound — warmer, fuller, more robust, with an open voice. The idea was to combine his interpretation of that older, traditional sound with the other fundamental sonic improvements that V-Class could deliver, like increased volume, sustain and pitch accuracy, along with signature Taylor attributes like an ultra-playable and easily serviceable Taylor neck.

With a sound in mind, Andy could focus on the key design elements that would help him produce it. In this case, especially to create a dramatically different voice, he needed to think about more than just a new iteration of V-Class. He needed a new recipe with other different ingredients because of the ways the components work together as a nuanced system. In this case, it was a combination of a new body style, new bracing and a new neck joint.

The Body: A Super Auditorium

The body design naturally was an important consideration. To help coax a warmer, more robust response from the guitar, Andy started with Taylor’s existing Grand Auditorium body style and made subtle but impactful modifications. The new body’s dimensions are similar, but the proportions have changed — the body is slightly longer, and the lower bout is a bit wider, creating what Andy describes as a “classically proportioned set of curves.” He designed it to be offered exclusively as a full-bodied (non-cutaway) model initially, with the possibility of making a cutaway version down the road. Because of its family relationship to the Grand Auditorium, we’re calling it the Super Auditorium.

The Bracing: Fanned V-Class

Andy also designed a new variant of his V-Class architecture that combines some of the V structure in the upper bout with a fan-like arrangement of braces in the soundboard’s lower bout — an influence from the classical guitar tradition. The fanned pattern, Andy says, helps produce a more pronounced richness in the midrange frequencies. The braces and other internal components also are set in place using hot hide glue, which references a long-used approach from past eras of guitar making. It’s something Andy had used for a time when he redesigned Taylor’s 800 Series in 2014 to optimize sound transfer.

The Neck Joint: Long-Tenon

The revolutionary neck joint design that Bob Taylor introduced back in 1999 was a game changer for us in terms of creating a more stable, resilient and micro-adjustable neck that enabled optimal playability, serviceability and longevity. Andy was committed to preserving those advanced performance virtues, but also saw an opportunity to modify the design to influence the sound in a different way.

His new design incorporates a proprietary long-tenon neck joint, which extends deeper into the guitar body, in this case all the way into an internal heel block. (Electric players might be familiar with a version long-tenon necks from some Les Paul models and other electric brands, though this version is considerably different.)

“This neck joint and heel structure have really good coupling to create tone,” Andy says. “It’s similar to the type of neck and body coupling associated with traditional neck designs, so you can add those ingredients into the sonic recipe.”

But unlike a dovetail-style neck (and like Bob’s neck design), this neck joint remains glueless to enable even easier and more precise neck angle micro-adjustability.

Two Wood Pairings

Andy wanted to introduce the Gold Label Collection with a rosewood guitar because of rosewood’s rich heritage in the acoustic guitar world. He chose Honduran rosewood, which he loves for its harmonic richness (with even more density and harmonic content than Indian rosewood) and which we currently use in our Presentation, 900 Series and new Builder’s Edition 814ce models. He also chose to make a model with back and sides of Hawaiian koa, which share similarities with mahogany’s tonal properties. Both feature torrefied Sitka spruce tops.

The Gold Label Sound

The sonic differences between a Gold Label guitar and a similar model from the existing Taylor line are immediately apparent. For example, take an A/B comparison between a Honduran rosewood/spruce Gold Label model and a rosewood/spruce Builder’s Edition 814ce.

“When you play the rosewood/spruce Builder’s Edition 814ce,” Andy says, “you’ll hear the most vivid expression of that modern Taylor sound players love — crisp, brilliant, chimey, piano-like and ultra-linear. When you lay into a rosewood/spruce Gold Label guitar, the sound will strike you in a very different way — bolder, warmer, thicker. It projects back at you in a way a modern guitar isn’t voiced to do, all the way from the low register through the midrange and the high end. It feels like the guitar is giving you back more sound than the effort you put into it.”

The voicing, he says, enables a uniquely dynamic response.

“When you play aggressively, its projection will respond with less of a perceived ceiling,” he explains. “It naturally amplifies the sound with a focused, dynamic tone rather than becoming mushy. Yet these guitars also respond to delicate articulation with a broadly rich voice. When you play a simple note softly, the guitar naturally amplifies it with surprising warmth and volume.”

An Aesthetic Identity Rooted in the Past

Andy has always had a strong belief that there should be a cohesion between the look and sound of a guitar — that the aesthetics should signal its musical personality. In this case especially, where he wanted to visually announce that this was a bold new voicing addition to the Taylor line, he revamped some of the visual design elements most closely associated with Taylor, including the shape of the headstock, pickguard and even the logo. In the same way the sound draws inspiration from the past, so does the look.

The decorative design aesthetic references several sources from the past, including banjos and mandolins, early Taylor designs, and Andy’s own pre-Taylor design work on his own guitars.

“The visual aesthetic is important for these guitars,” Andy says. “When I play an instrument, it seems to me the appearance should align with the sound and feel to complete the picture. Experiencing the sound and feel of this guitar, it felt like the aesthetic identity should reflect the different playing experience. At the same time, I wanted a different presentation to invite players to experience the guitar with a fresh perspective.”

Highlights of the aesthetic details include:

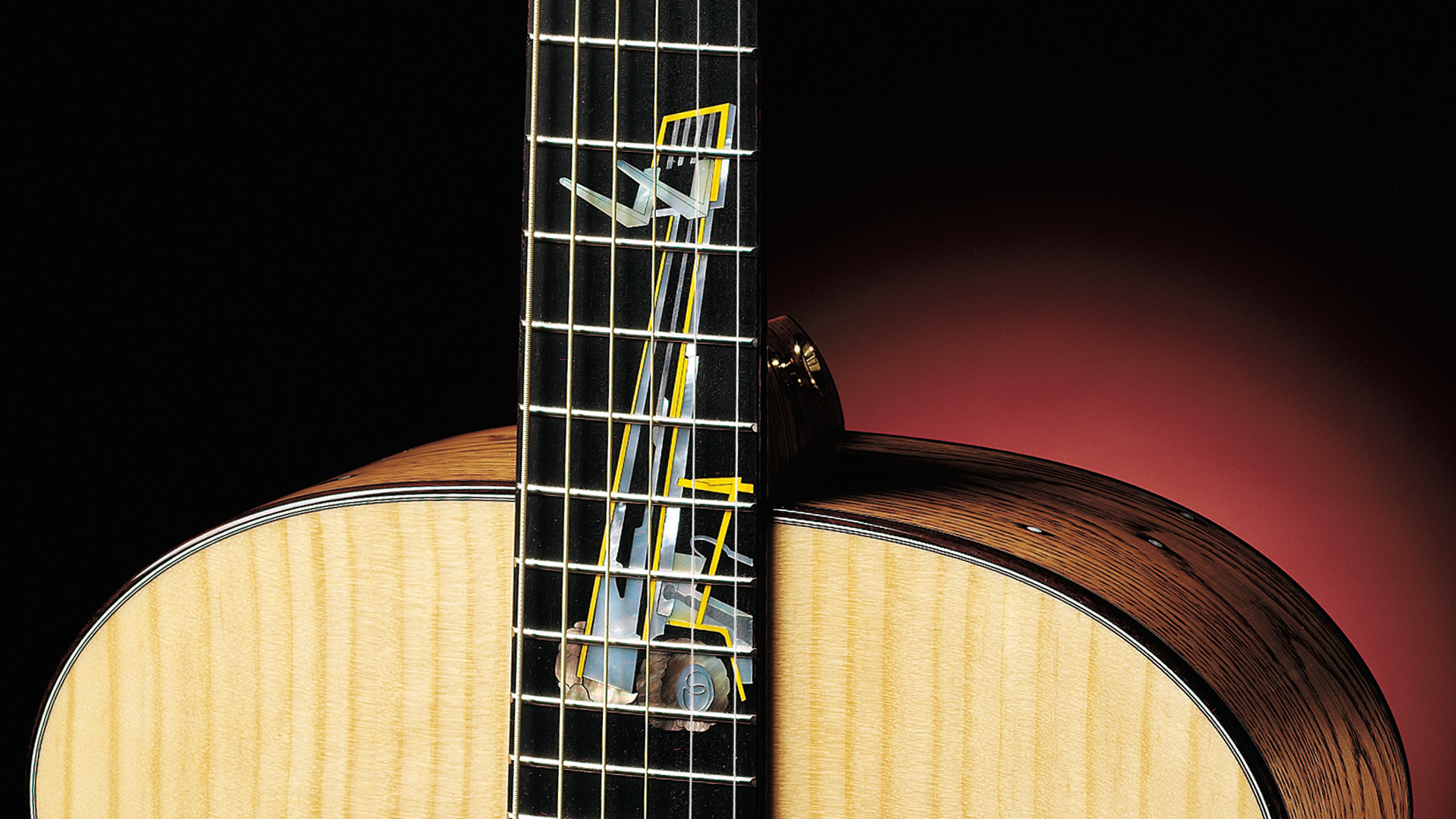

A new headstock and logo design: Look closely at the top of the headstock and you’ll see the design legacy of the classic Taylor headstock partially represented with two scoops and two points on either side. But instead of a third scoop in the middle, the line is rounded — a design element borrowed from the headstock of archtop guitars that Andy crafted in his pre-Taylor days.

Another distinction is an angled back cut along the top edge of the headstock. “That attribute borrows from the banjo, mandolin and early archtop guitar tradition,” Andy says. “It’s something that went out of style for guitars back in the ’20s and early ’30s, but I think it looks pretty.”

A different version of the Taylor logo is based on Andy’s hand-drawn reinterpretation.

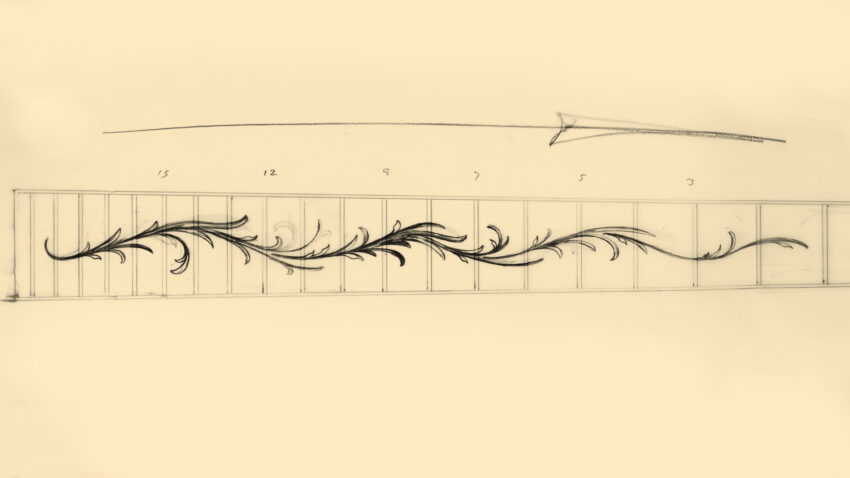

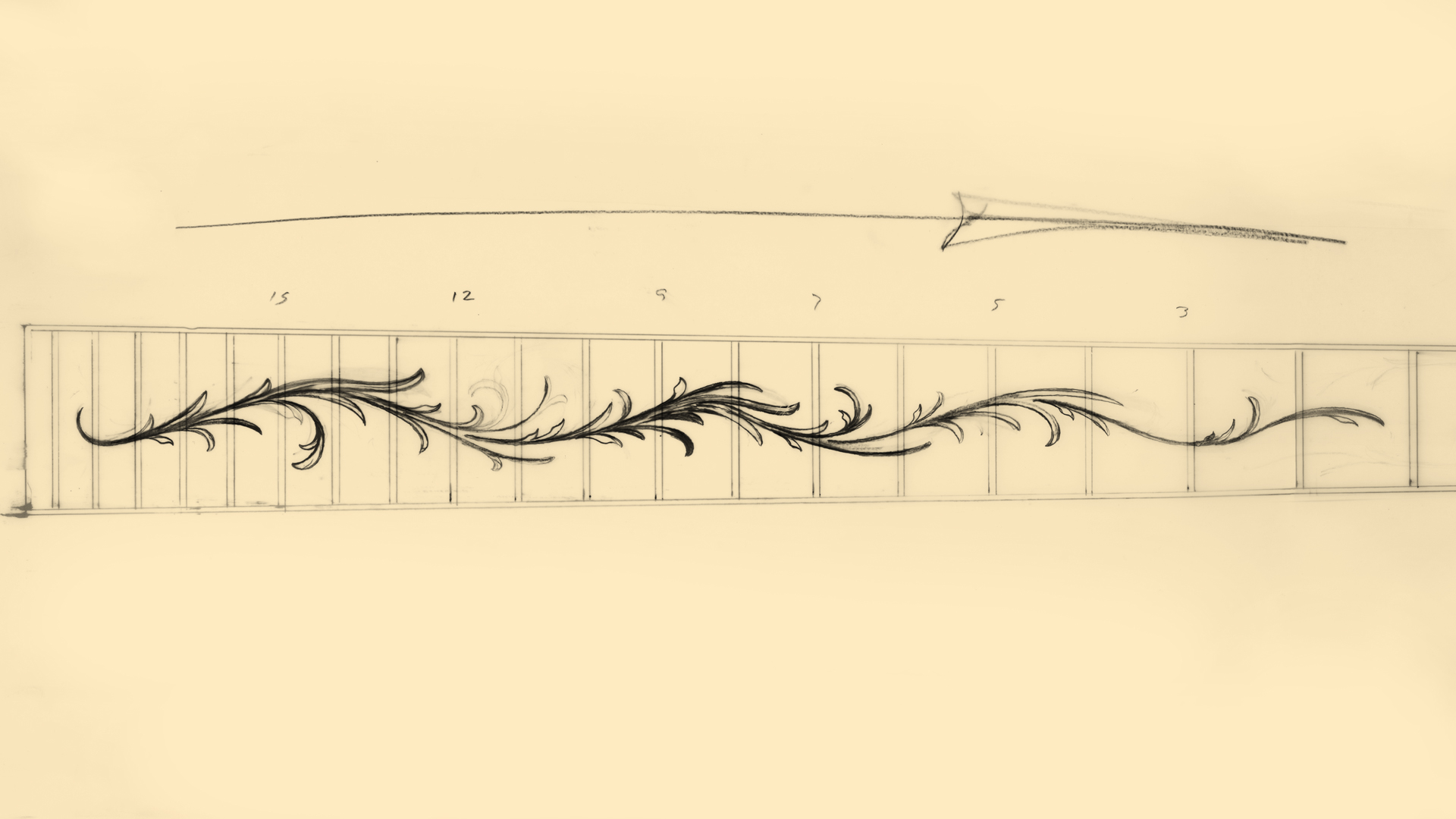

A new inlay suite: “The inlay motif tips its hat to the earliest Taylor work and is pared down into the line weights and interlocked negative space flourishes seen on early mandolins and banjos,” Andy explains. He named the design “Continental,” a name that came to him when he was in Chicago for a guitar conference. “I was looking at an old ironwork bracket that held up a sign outside a bookshop, and it reminded me of this inlay pattern,” he says. “Around the same time, I happened to see a ’56 Lincoln Continental drive by. It’s a rare car to see in the wild, and a longtime favorite of mine. The name stuck.”

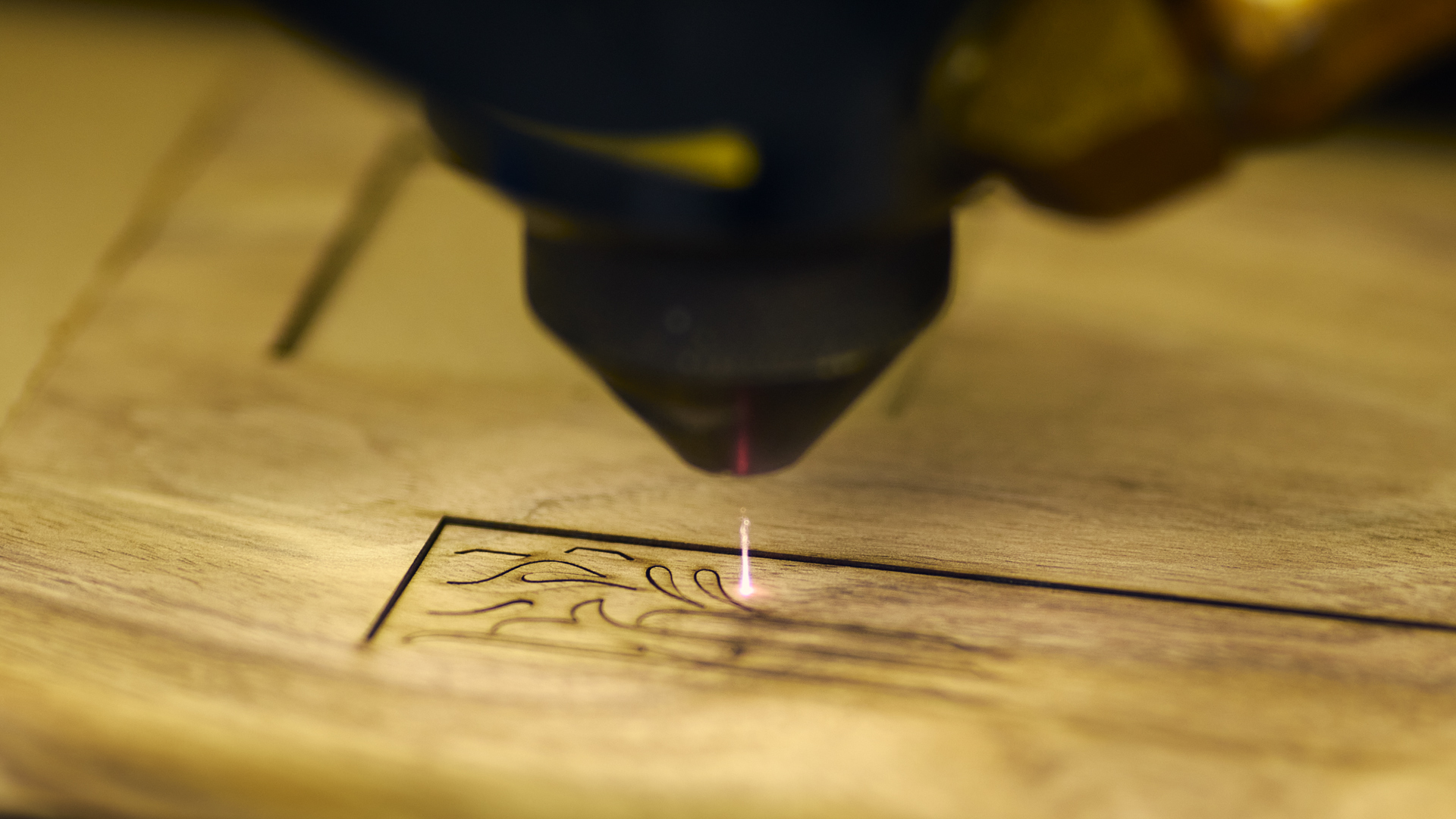

A new pickguard design: The pickguard showcases several unique design elements. The shape, Andy says, references some of Taylor’s pickguard design heritage, “plus the elliptical curves I was fond of using on my earliest designs.” It also incorporates a two-ply, dual-material construction of faux-tortoiseshell over grained ivoroid with a decorative Continental motif. What looks like an inlay from afar is an engraved cutout through the tortoise top layer, which reveals the grained ivoroid layer beneath it. Though we use a CNC mill to do the engraving work, Andy drew inspiration from the banjo and archtop guitar tradition from the ’20s and ’30s of hand-engraving through multi-layer celluloid to reveal alternate colors underneath.

“The archtop guitar peghead designs of Elmer Stromberg were favorite examples of this technique, as were a few early Epiphone archtop guitars and mandolins,” he says.

A new bridge design: The bridge shape borrows our “Curve Wing” shape featured on Builder’s Edition models, but the material is Honduran rosewood rather than ebony. “This choice of different materials for the fretboard and bridge borrows from the classical guitar tradition, where it’s customary to use dense ebony for the fretboard and a dense rosewood for the bridge,” Andy says. “While the steel-string guitar tradition commonly uses the same material for the bridge and fretboard, there are interesting tonal nuances with this varied approach.” Another subtle material refinement is the use of bone bridge pins.

Meet the Models

Within the Taylor line, thenew Gold Label Collection sits apart as its own distinctive class of premium-edition models comparable to the Builder’s Edition Collection. Like the debut of Builder’s Edition, this collection will start small and grow over time.

The guitars will follow a similar model numbering convention to our Builder’s Edition Collection, featuring the collection name followed by the numerical approach used for other standard models — with a couple of notable distinctions. First, since the guitars will be priced comparably to our Builder’s Edition 814ce, both the rosewood and koa models will have an 800 Series designation. Second, because of the Super Auditorium body style’s similarity to the Grand Auditorium, the models will also be identified with a 4 as the third digit. (The Super Auditorium shape will be exclusive to the Gold Label Collection.)

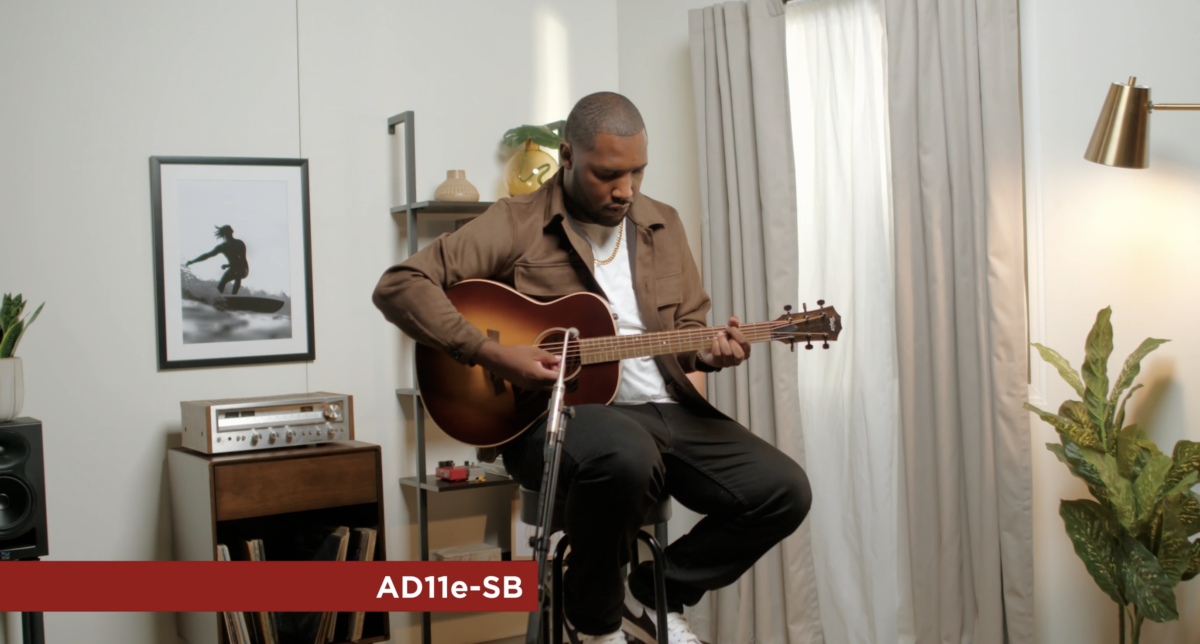

As referenced earlier, the two back and side tonewood options are Honduran rosewood and figured Hawaiian koa, each paired with a torrefied Sitka spruce top. Both will be offered with the choice of a natural or burst top. The four models are:

Honduran Rosewood / Torrefied Sitka Spruce

Gold Label 814e (natural top)

Street Price: $4,499

Gold Label 814e SB (sunburst top)

Street Price: $4,699

Figured Hawaiian Koa / Torrefied Sitka Spruce

Gold Label 814e Koa (natural top)

Street Price: $4,799

Gold Label 814e Koa SB (sunburst top)

Street Price: $4,999

Looking ahead to the Gold Label Collection’s official industry debut at the NAMM Show in January, Andy Powers is as excited as he’s ever been to usher a new guitar into the world. It stems in part from being able to showcase V-Class’s dramatic tone-shaping power in a whole different light, and from the prospect of appealing to a wider array of players.

“I feel fortunate to live during a time when we’re able to capture some of the best-loved sonic characteristics of classic steel-string guitars and bring that into a modern context in terms of playability, accurate notes, build quality and serviceability,” he says. “I feel like it gives players the best of all worlds.”

To learn more about the Gold Label Collection, explore the 2025 digital Taylor Guitars product guide. For complete specifications and additional video content, visit TaylorGuitars.com.